Plastic injection molding machine

equipped with advanced single injection cylinder design, which is self-innovated and patented by Lanson. We have about 30 self patents nationally.

Product Advantages:

GT3 series plastic injection molding machine equipped with advanced single injection cylinder design, which is self-innovated and patented by Lanson. Integrating mature single injection cylinder technology and employing cutting-edge industrial concept and technical research platform, it features precision, fast response, high efficiency and energy saving. We have about 30 self patents nationally.

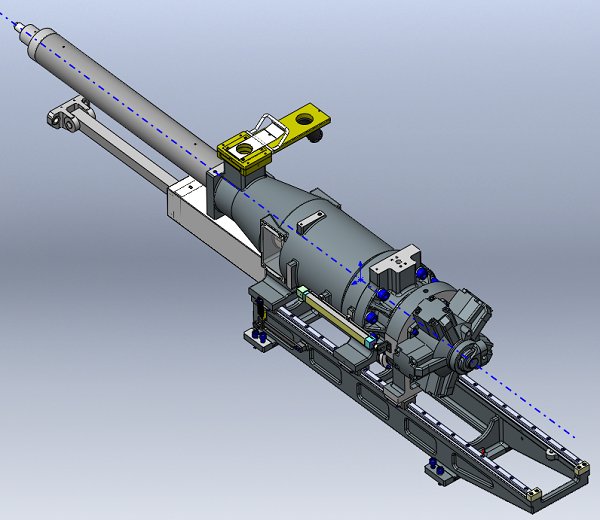

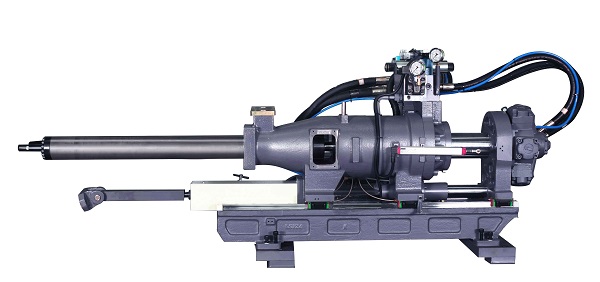

Single Injection Cylinder with linear guide way

Co-axial with screw & plasticizing motor, increase the injection pressure and speed. Have a fast and accurate injection performance. A new single cylinder injection system with more efficient injection performance, more compact design, higher injection pressure, for more sophisticated injection product. This special Injection unit front plate makes better concentric for screw and nozzle.

Low friction hydraulic design, minimize the injection resistance, fast response, ultra speed, more energy saving.

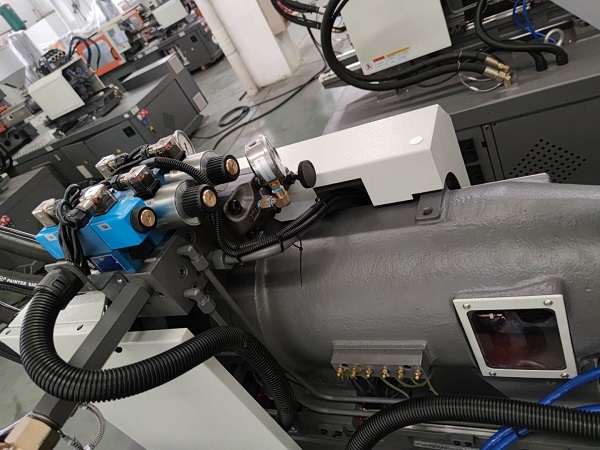

There is a window for monitoring screw rotation

Injection action connect with control valve rigidity

Effective decrease fluid fluctuation and increase injection precision (different model different valves)

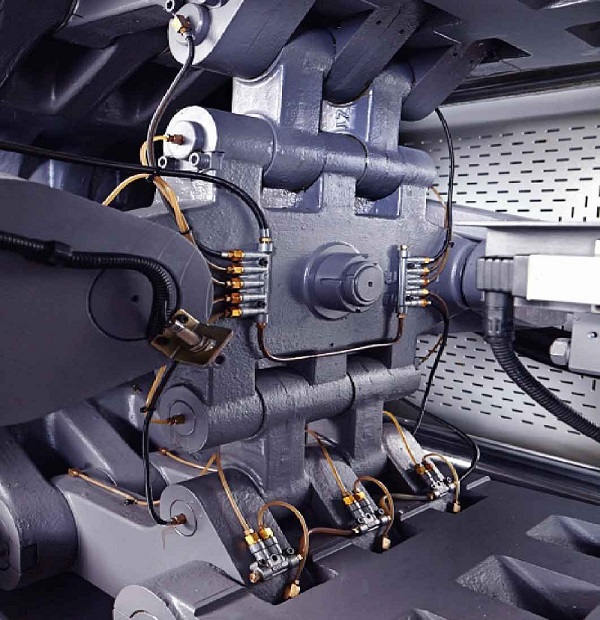

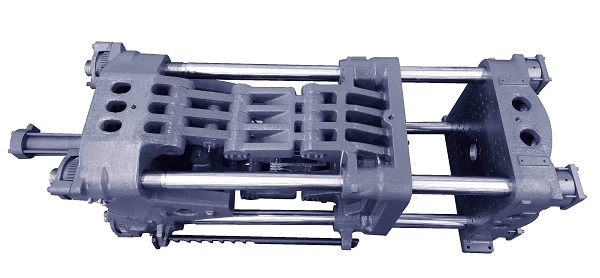

Reinforced Crosshead

The crosshead has wide and thick structure, strong structural rigidity and long service life

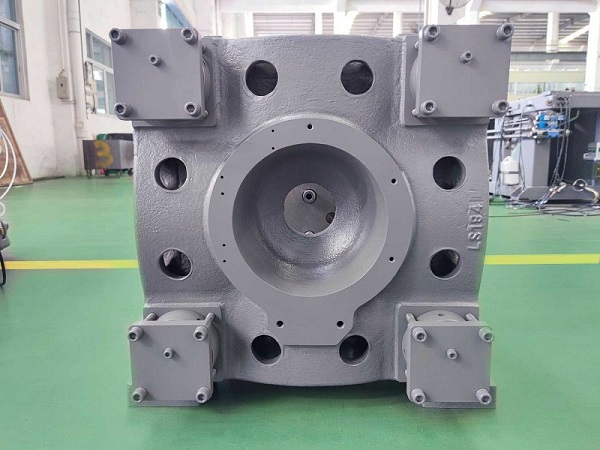

Optimized fixed platen design ( 60T to 260T)

The fixed platen employed the patented design of our company “arched molding platen”, stress will disperse out. As a result of no stress concentration, service life of molding platen is extended . Optimized strengthen moving platen with better stress uniform and longer service life. Distortion of platen is strictly controlled by finite element analysis.

Widened toggle with longer service life

In order to increase the service life of hinge pin and steel jacket, we increase the number of hinges pins and steel jackets shearing surface.

Through widened hinge ears of moving platen, the stress received by molding board is dispersed equally and avoid stress concentration.

Intelligent controller & Servo power system

A high-performance, new-generation inelligent computer controller with rotatable control panel.

Servo-drive system guarantees the highest response, highest precision and lowest power consumption.

X

X