Baisheng Robotic Arm Laser Cutting and Welding Machine for 3D Processing

Laser Robotic Arm Cutting Machine is very popular in 3D welding and cutting industries.So many integrations of a robotic arm into a CNC cutter.

According to real application ,the tables for cutting ,welding parts are different ,using differenct chucks ,clap. User can customize it .

When changing welding head to cutting head ,need changing the coordinate system.

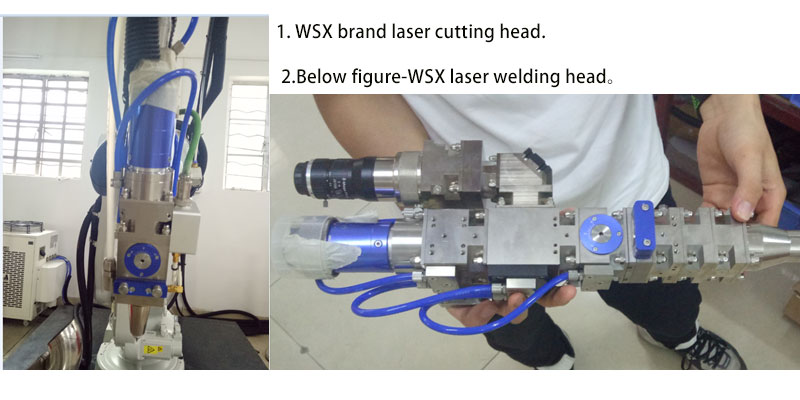

Figures of Robotic Arm Fiber Laser Details

According to different application ,head options for the Robotic laser.

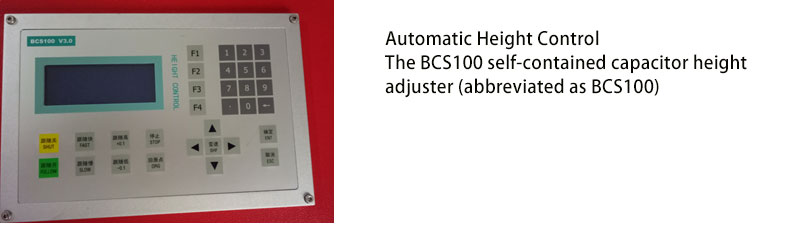

Automatic Height Control

The BCS100 self-contained capacitor height

adjuster (abbreviated as BCS100) adopts a closed-loop control method to control

the laser-cutting capacitor follower and provides a unique Ethernet communication

(TCP/IP protocol) interface.

It is easy to implement high-speed automatic tracking and sharing with Cypcut software.

Section perforation, progressive

perforation, edge-seeking cutting, frog-leaping lifting, cutting head elevation

setting, flight optical path compensation,etc.

The BCS100 adopts a double-closed-loop algorithm with speed and position. Its performance, such as speed and accuracy, is significantly better than similar products at domestic and abroad market.

Handheld Console

The remote wireless remote controller allows the operator to perform most operations from any convenient location: starting and stopping the program, lighting out, following, reversing the contour, increasing/decreasing the focal length, changing the feed rate, and outputting machine parts.

X

X