Aluminum alloy characteristic ability of high temperature butterfly valve, apply pressure range is higher also, nominal valve size is big, the body is made of carbon steel, the valve plate seal aluminum ring is used to replace the rubber ring, apply to the hvac, central air conditioning, fluctuation of complete sets of equipment, lack of application in the: water, gas, oil, chemical industry, metallurgy, energy, shipbuilding, electric power, petroleum, water treatment, construction and other industries.

Aluminum Alloy Butterfly Valve Series

Aluminum alloy butterfly valve refers to the closing piece (disc or butterfly plate) for aluminum alloy material.

Aluminum alloy characteristic ability of high temperature butterfly valve, apply pressure range is higher also, nominal valve size is big, the body is made of carbon steel, the valve plate seal aluminum ring is used to replace the rubber ring, apply to the hvac, central air conditioning, fluctuation of complete sets of equipment, lack of application in the: water, gas, oil, chemical industry, metallurgy, energy, shipbuilding, electric power, petroleum, water treatment, construction and other industries.

Product features

1 The structure is simple and the shape sesign is novel and unique. Font clear, smooth surface,spray treatment of valve body.

2 Light torque, light weight, various colors, easy to transport and install.(if equipped with electric actuator,lower gear can be selected).

3 the top flange adopts ISO5211 and GB/T12223 double position installation without adapter plate.

4 The valve rod is precision processed to ensure concentricity,with anti flying groove to prevent the valve rod from flying out.

5 The butterfly valve adopts non pin shaft plate connection,rotation and bidirectional butterfly valve installation to provide reliabilirty and easy installation.

6 Valve seat design provides complete separation of valve body and valve stem from medium, with pressure of 18kg and no leakage.

7 Site maintenance provides convenience to remove the damaged valve seat.Replace the vavle seat with a new one.

8 The valve body is made of high-pressure standard aluminum alloy die-casting,which is fast in delivery,free from environmental impact and anti condensation.The pressure of clamp is 60 tons without deformation,and the pressure bearing pressure can reach 3.5tons.

|

Technical Parameter |

||||||

| Nominal Diameter | Nominal Pressure | Body Material | Valve Plate Material | Seat Material | Using Media | Driving Mode |

| DN25-DN300 |

PN10-PN16, 5K-10K |

Aluminium Alloy |

Nodular Iron Zinc Plating, Ductile Iron,304,316,316L, 2507,1.4529. |

EPDM,Nbrtemperature Resistant Ethylene Propylene,Wear-resistant Ethylene Propylene Fluororubber,Silicone Rubber. |

Water,Sea water, Air,Food,Oil,Slurry, Dust,Ect. |

Manual,Electric,Pneumatic And Hydraulic. |

|

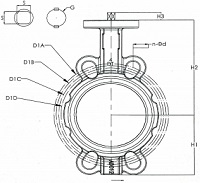

Main Dimensions |

||||||||||||

|

NPS |

DN |

L |

150LB | PN16 | PN10 | 5K | 10K | 150LB | PN16 | PN10 | 5K | 10K |

| D1A | D1B | D1C | D1D | D1A | n-φd |

n-φd |

n-φd |

n-φd |

n-φd |

|||

| 1/1.25 | 25/32 | 33 | 98.4 | 110 | 110 | 90 | 105 | 4-19 | 4-18 | 4-18 | 4-12 | 4-16 |

| 1.5/2 | 40/50 | 42.5 | 120.7 | 125 | 125 | 105 | 120 | 4-19 | 4-18 | 4-18 | 4-15 | 4-16 |

| 2.5 | 65 | 46 | 139.7 | 145 | 145 | 130 | 140 | 4-19 | 8-18 | 8-18 | 4-15 | 4-16 |

| 3 | 80 | 46 | 152.4 | 160 | 160 | 145 | 150 | 4-19 | 8-18 | 8-18 | 8-19 | 8-16 |

| 4 | 100 | 52 | 190.5 | 180 | 180 | 165 | 175 | 8-19 | 8-18 | 8-18 | 8-19 | 8-16 |

| 5 | 125 | 55.4 | 215.9 | 210 | 210 | 200 | 210 | 8-22 | 8-18 | 8-18 | 8-19 | 8-20 |

| 6 | 150 | 55.8 | 241.3 | 240 | 240 | 230 | 240 | 8-22 | 8-22 | 8-11 | 8-19 | 8-20 |

| 8 | 200 | 60 | 298.5 | 195 | 295 | 280 | 290 | 8-22 | 12-22 | 8-22 | 8-23 | 12-20 |

| 10 | 250 | 66.5 | 362 | 355 | 350 | 345 | 355 | 12-26 | 12-26 | 12-22 | 12-23 | 12-22 |

| 12 | 300 | 77.5 | 413.8 | 410 | 400 | 390 | 400 | 12-26 | 12-26 | 12-22 | 12-23 | 16-22 |

PN10&PN16&150LB/5K~10K

|

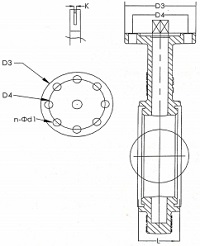

Main Dimensions |

||||||||||

| NPS | DN | H1 | H2 | H3/Square shaft | H4/Circular shaft | S*S/G | K | D3 | D4 | n-φd1 |

| 1/1.25 | 25/32 | 56 | 96 | 14 | 28 | 9*9/12.6 | 3 | 72 | 50/57 | 8-7 |

| 1.5/2 | 40/50 | 72 | 133 | 14 | 28 | 9*9/12.6 | 3 | 70 | 50/57 | 8-7 |

| 2.5 | 65 | 86 | 142 | 14 | 28 | 9*9/12.6 | 3 | 70 | 50/57 | 8-7 |

| 3 | 80 | 95 | 149 | 14 | 28 | 9*9/12.6 | 3 | 70 | 50/57 | 8-7 |

| 4 | 100 | 108 | 173 | 18 | 28 | 11*11/15.8 | 5 | 90 | 70/70 | 8-10 |

| 5 | 125 | 125 | 182 | 18 | 28 | 14*14/18.9 | 5 | 90 | 70/70 | 8-10 |

| 6 | 150 | 139 | 199 | 18 | 28 | 14*14/18.9 | 5 | 90 | 70/70 | 8-10 |

| 8 | 200 | 170 | 238 | 25 | 35 | 17*17/22.1 | 5 | 125 | 102/89 | 4-12/14 |

| 10 | 250 | 207 | 283 | 30 | 40 | 22*22/28.45 | 8 | 125 | 102/89 | 4-12/14 |

| 12 | 300 | 236 | 309 | 30 | 40 | 22*22/31.6 | 8 | 140 | 102/108 | 4-12/14 |

Packing & Delivery :

Packing Details : all by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details : Generally it is 5-10 days if the goods are in stock. or 15-30 days if the goods are OEM or not enough subject to the order quantity. But anyway,normally, we are able to make sure the delivery will not exceed 45 days.

X

X