A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball (called a "floating ball") to control flow through it. It is open when the ball's hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle.[1] The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve's status

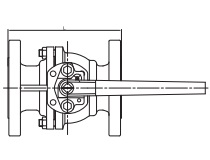

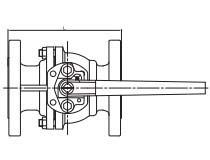

2 pieces ball valve flange end

Q41F ball valve flange end it has the same rotation 90 degrees action, the difference is that the cock body is a sphere with a circular through hole or channel through its axis. Ball valve in the pipeline is mainly used to cut off, distribute and change the flow direction of the medium, it only needs to rotate 90 degrees operation and very small rotation torque to close tight. Q41F ball valve classification: stainless steel Q41F ball valve, wide Q41F ball valve, carbon steel Q41F ball valve, integrated Q41F ball valve, three-piece Q41F ball valve.

DIN Features:

Full port,1/2"-12"(DN15~DN300)

W.P.: PN16/40

W.T.: -20℃-180℃

Investment casting

Blow-out proof stem

Anti-static device (option)

Locking device handle

ISO 5211 Direct mounting pad

Automation accessories (option)

Design: EN1983, EN12516-1

Flange dimension: DIN 2543~2545, EN1092-1 PN16/40

Face to face: DIN3202 Part1-F4(DN15~dn100),DIN3202 Part1-F5(DN125~DN300)

Inspection & testing:DIN3230,EN12266-1

|

Material List |

||||

| No. |

PARTS |

MATERIAL |

||

| 1 | BODY |

1.0619 |

1.4308 |

1.4408 |

| 2 | BOLT |

304 |

||

| 3 | NUT |

304 |

||

| 4 | BALL |

1.4308 |

1.4308 | 1.4408 |

| 5 | SEAT |

PTFE |

||

| 6 | BODY | 1.0619 | 1.4308 | 1.4408 |

| 7 | STEM | 304 | 304 | 316 |

| 8 | GASKET |

PTFE |

||

| 9 | O-RING |

FPM |

||

| 10 | HEX SOCKET BOLT |

304 |

||

| 11 | PACKING |

PTFE |

||

| 12 | BONNET | 1.0619 | 1.4308 | 1.4408 |

| 13 | GLAND | 304 | ||

| 14 | HANDLE |

WCB/CF8 |

||

| 15 | STEM WASHER | PTFE+25%GF | ||

| 16 | STEM WASHER | PTFE+25%GF | ||

Unit:mm

|

Dimensions PN16 |

|||||||||||||||||

|

Nominal Diameter |

L |

d |

D2 |

D1 |

D |

b |

f |

n-φd1 |

H |

h |

W |

Ra |

Rb |

A |

B |

KxK |

|

|

15 |

1/2" |

115 | 15 |

45 |

65 | 95 | 16 | 2 | 4-14 | 55 | 9 | 140 | 3.0 | 3.5 | 36 | 50 | 9X9 |

| 20 | 3/4" | 120 | 20 | 58 | 75 | 105 | 18 | 2 | 4-14 | 60 | 9 | 140 | 3.0 | 3.5 | 36 | 50 | 9X9 |

| 25 | 1" | 125 | 25 |

68 |

85 | 115 | 18 | 2 | 4-14 | 67 | 11 | 170 | 3.0 | 3.5 | 36 | 50 | 11X11 |

| 32 | 1-1/4" | 130 | 32 |

78 |

100 | 140 | 18 | 2 | 4-18 | 76 | 11 | 170 | 3.0 | 3.5 | 42 | 50 | 11X11 |

| 40 | 1-1/2" | 140 | 40 |

88 |

110 | 150 | 18 | 3 | 4-18 | 85 | 14 | 200 | 3.5 | 4.5 | 50 | 70 | 14X14 |

| 50 | 2" | 150 | 50 |

102 |

125 | 165 | 20 | 3 | 4-18 | 93 | 14 | 200 | 3.5 | 4.5 | 50 | 70 | 14X14 |

| 65 | 2-1/2" | 170 | 65 |

122 |

145 | 185 | 18 | 3 | 4-18 | 113 | 17 | 300 | 4.5 | 5.5 | 70 | 102 | 17X17 |

| 80 | 3" | 180 | 80 |

138 |

160 | 200 | 20 | 3 | 8-18 | 126 | 17 | 300 | 4.5 | 5.5 | 70 | 102 | 17X17 |

| 100 | 4" | 190 | 100 |

158 |

180 | 220 | 20 | 3 | 8-18 | 141 | 17 | 300 | 4.5 | 5.5 | 70 | 102 | 17X17 |

| 125 | 5" | 325 | 125 |

188 |

210 | 250 | 22 | 3 | 8-18 | 170 | 25 | 650 | 5.5 | 6.5 | 102 | 125 | 22X22 |

| 150 | 6" | 350 | 150 | 212 | 240 | 285 | 22 | 3 | 8-22 | 192 | 30 | 800 | 5.5 | 6.5 | 102 | 125 | 27X27 |

| 200 | 8" | 400 | 200 | 268 | 295 | 340 | 24 | 3 | 8-22 | 234 | 35 | 300 | 5.5 | 6.5 | 102 | 125 | 27X27 |

Unit:mm

|

Dimensions PN40 |

|||||||||||||||||

|

Nominal Diameter |

L |

d |

D2 |

D1 |

D |

b |

f |

n-φd1 |

H |

h |

W |

Ra |

Rb |

A |

B |

KxK |

|

|

15 |

1/2" |

115 | 15 | 45 | 65 | 95 | 16 | 2 | 4-14 | 55 | 9 | 140 | 3.0 | 3.5 | 36 | 50 | 9X9 |

| 20 | 3/4" | 120 | 20 | 58 | 75 | 105 | 18 | 2 | 4-14 | 60 | 9 | 140 | 3.0 | 3.5 | 36 | 50 | 9X9 |

| 25 | 1" | 125 | 25 | 68 | 85 | 115 | 18 | 2 | 4-14 | 67 | 11 | 170 | 3.0 | 3.5 | 42 | 50 | 11X11 |

| 32 | 1-1/4" | 130 | 32 | 78 | 100 | 140 | 18 | 2 | 4-18 | 76 | 11 | 170 | 3.0 | 3.5 | 42 | 50 | 11X11 |

| 40 | 1-1/2" | 140 | 40 | 88 | 110 | 150 | 18 | 3 | 4-18 | 85 | 14 | 200 | 3.5 | 4.5 | 50 | 70 | 14X14 |

| 50 | 2" | 150 | 50 | 102 | 125 | 165 | 20 | 3 | 4-18 | 93 | 14 | 200 | 3.5 | 4.5 | 50 | 70 | 14X14 |

| 65 | 2-1/2" | 170 | 65 | 122 | 145 | 185 | 22 | 3 | 8-18 | 113 | 17 | 300 | 4.5 | 5.5 | 70 | 102 | 17X17 |

| 80 | 3" | 180 | 80 | 138 | 160 | 200 | 24 | 3 | 8-18 | 126 | 17 | 300 | 4.5 | 5.5 | 70 | 102 | 17X17 |

| 100 | 4" | 190 | 100 | 168 | 190 | 235 | 24 | 3 | 8-22 | 141 | 22 | 650 | 5.5 | 6.5 | 102 | 125 | 22X22 |

| 125 | 5" | 325 | 125 | 188 | 220 | 270 | 26 | 3 | 8-26 | 170 | 25 | 650 | 5.5 | 6.5 | 102 | 125 | 22X22 |

| 150 | 6" | 350 | 150 | 218 | 250 | 300 | 28 | 3 | 8-26 | 192 | 30 | 800 | 5.5 | 6.5 | 102 | 125 | 27X27 |

| 200 | 8" | 400 | 200 | 285 | 320 | 375 | 34 | 3 | 12-30 | 234 | 35 | 300 | 5.5 | 6.5 | 102 | 125 | 27X27 |

ANSI Features:

Full port, 1/2"-12"(DN15-DN300)

W.P.: CLASS 150/300

W.T.: -20℃-180℃

Investment casting

Blow-out proof stem

Anti-static device (option)

Design: ASME B16.34,API608,API6D

Flange dimension: ASME B16.5

Face to face: ASME B16.10

Inspection&testing: API598

Material List |

||||

| No. |

PARTS |

MATERIAL |

||

|

1 |

BODY | WCB | CF8 | CF8M |

|

2 |

SEAT |

PTFE |

||

| 3 | BALL | CF8 | CF8 | CF8M |

| 4 | GASKET |

PTFE |

||

|

5 |

BONNET | WCB | CF8 | CF8M |

|

6 |

BOLT |

304 |

||

|

7 |

NUT |

304 |

||

|

8 |

STEM | 304 | 304 | 316 |

| 9 | STME WASHER |

PTFE+25% GF |

||

| 10 | O-RING |

FPM |

||

| 11 | PACKING |

PTFE |

||

| 12 | WAEA WASHER |

PTFE+25% GF |

||

| 13 | GLAND |

CF8 |

||

| 14 | STOPPER |

304 |

||

|

15 |

CIRCLIPS FOR SHAFT |

304 |

||

| 16 | HANDLE |

WCB |

||

|

17 |

WASHER |

304 |

||

|

18 |

BOLT |

304 |

||

| 19 | BOLT |

304 |

||

Unit:mm

Dimensions CLASS150 |

||||||||||||||

|

Nominal Diameter |

L |

d |

D2 |

D1 |

D |

b |

f |

n-φd1 |

H |

W | A |

4-M |

KxK |

|

|

15 |

1/2" |

108 | 15 | 35 | 60.3 | 90 | 8 | 2 | 4-16 | 73 | 133 | 42 | 4-M5 | 9X9 |

|

20 |

3/4" | 117 | 20 | 43 | 70 | 100 | 8.9 | 2 | 4-16 | 76 | 133 | 42 | 4-M5 | 9X9 |

|

25 |

1" | 127 | 25 | 51 | 79.4 | 110 | 9.6 | 2 | 4-16 | 92 | 163 | 50 | 4-M6 | 11X11 |

|

32 |

1-1/4" | 140 | 32 | 63.5 | 88.9 | 115 | 11.2 | 2 | 4-16 | 95 | 163 | 50 | 4-M6 | 11X11 |

| 40 | 1-1/2" | 165 | 40 | 73 | 98.4 | 125 | 12.7 | 2 | 4-16 | 116 | 192 | 70 | 4-M8 | 14X14 |

|

50 |

2" | 178 | 50 | 92 | 120.7 | 150 | 14.3 | 2 | 4-19 | 123 | 192 | 70 | 4-M8 | 14X14 |

|

65 |

2-1/2" | 190 | 65 | 105 | 139.7 | 180 | 15.9 | 2 | 4-19 | 150 | 330 | 70 | 4-M8 | 17X17 |

|

80 |

3" | 203 | 80 | 127 | 152.4 | 190 | 17.5 | 2 | 4-19 | 165 | 330 | 102 | 4-M10 | 19X19 |

|

100 |

4" | 229 | 100 | 157 | 190.5 | 230 | 22.3 | 2 | 8-19 | 180 | 330 | 102 | 4-M10 | 19X19 |

|

125 |

5" | 356 | 125 | 185 | 216 | 255 | 22.3 | 2 | 8-22 | 217 | 398 | 125 | 4-M12 | 22X22 |

|

150 |

6" | 394 | 150 | 216 | 241.3 | 280 | 23.9 | 2 | 8-22 | 192 | 30 | 102 | 4-M12 | 27X27 |

| 200 | 8" | 457 | 200 | 270 | 298.5 | 345 | 27 | 2 | 8-22 | 234 | 35 | 102 | 4-M12 | 27X27 |

Dimensions CLASS300 |

||||||||||||||

|

Nominal Diameter |

L |

d |

D2 |

D1 |

D |

b |

f |

n-φd1 |

H |

W | A |

4-M |

KxK |

|

|

15 |

1/2" |

140 | 15 | 35 | 66.7 | 95 | 12.7 | 2 | 4-16 | 73 | 133 | 42 | 4-M5 | 9X9 |

|

20 |

3/4" | 152 | 20 | 43 | 82.6 | 115 | 14.3 | 2 | 4-19 | 76 | 133 | 42 | 4-M5 | 9X9 |

|

25 |

1" | 165 | 25 | 51 | 88.9 | 125 | 15.9 | 2 | 4-19 | 92 | 163 | 50 | 4-M6 | 11X11 |

|

32 |

1-1/4" | 178 | 32 | 63.5 | 98.4 | 135 | 17.5 | 2 | 4-19 | 95 | 163 | 50 | 4-M6 | 11X11 |

| 40 | 1-1/2" | 190 | 40 | 73 | 114.3 | 155 | 19.1 | 2 | 4-22 | 116 | 192 | 70 | 4-M8 | 14X14 |

|

50 |

2" | 216 | 50 |

92 |

127 | 165 | 20.7 | 2 | 8-19 | 123 | 192 | 70 | 4-M8 | 14X14 |

|

65 |

2-1/2" | 241 | 65 | 105 | 149.2 | 190 | 23.9 | 2 | 8-22 | 150 | 330 | 70 | 4-M8 | 17X17 |

|

80 |

3" | 282 | 80 | 127 | 168.3 | 210 | 27 | 2 | 8-22 | 165 | 330 | 102 | 4-M10 | 19X19 |

|

100 |

4" | 305 | 100 | 157 | 200 | 255 | 30.2 | 2 | 8-22 | 192 | 398 | 125 | 4-M12 | 19X19 |

|

125 |

5" | 381 | 125 | 185 | 216 | 280 | 33.4 | 2 | 8-22 | 170 | 25 | 102 | 4-M12 | 22X22 |

|

150 |

6" | 403 | 150 | 216 | 269.9 | 320 | 35 | 2 | 8-22 | 192 | 30 | 102 | 4-M12 | 27X27 |

| 200 | 8" | 502 | 200 | 270 | 330.2 | 380 | 39.7 | 2 | 8-22 | 234 | 35 | 102 | 4-M12 | 27X27 |

JIS Features:

Full port. 1/2"~6"(DN15-DN150)

W.P.: 10K/20K

W.T.: -20℃-180℃

Blow-out proof stem

Anti-static device (option)

Design: JIS B2071

Flange dimension: JIS B2220

Face to face: JIS B2002

Inspection&testing: JIS B2003

Material List |

||||

| No. |

PARTS |

MATERIAL |

||

|

1 |

BODY | SCPH2 | SCS13 | SCS14 |

|

2 |

SEAT |

PTFE |

||

| 3 | BALL | SCS13 | SCS13 | SCS14 |

| 4 | GASKET |

PTFE |

||

|

5 |

BONNET | SCPH2 | SCS13 | SCS14 |

|

6 |

BOLT |

304 |

||

|

7 |

NUT |

304 |

||

|

8 |

STEM | 304 | 304 | 316 |

| 9 | STME WASHER |

PTFE+25% GF |

||

| 10 | O-RING |

FPM |

||

| 11 | PACKING |

PTFE |

||

| 12 | WAEA WASHER |

PTFE+25% GF |

||

| 13 | GLAND |

CF8 |

||

| 14 | STOPPER |

304 |

||

|

15 |

CIRCLIPS FOR SHAFT |

304 |

||

| 16 | HANDLE |

WCB |

||

|

17 |

WASHER |

304 |

||

|

18 |

BOLT |

304 |

||

| 19 | BOLT | 304 | ||

Dimensions 10K |

||||||||||||||

|

Nominal Diameter |

L |

d |

D2 |

D1 |

D |

b |

f |

n-φd1 |

H |

W | A |

4-M |

KxK |

|

|

15 |

1/2" |

108 | 15 | 51 | 70 | 95 | 12 | 1 | 4-15 | 73 | 133 | 42 | 4-M5 | 9X9 |

|

20 |

3/4" | 117 | 20 | 56 | 75 | 100 | 14 | 1 | 4-15 | 76 | 133 | 42 | 4-M5 | 9X9 |

|

25 |

1" | 127 | 25 | 67 | 90 | 125 | 14 | 1 | 4-19 | 92 | 163 | 50 | 4-M6 | 11X11 |

|

32 |

1-1/4" | 140 | 32 | 76 | 100 | 135 | 16 | 2 | 4-19 | 95 | 163 | 50 | 4-M6 | 11X11 |

| 40 | 1-1/2" | 165 | 40 | 81 | 105 | 140 | 16 | 2 | 4-19 | 116 | 192 | 70 | 4-M8 | 14X14 |

|

50 |

2" | 178 | 50 | 96 | 120 | 155 | 16 | 2 | 4-19 | 123 | 192 | 70 | 4-M8 | 14X14 |

|

65 |

2-1/2" | 190 | 65 | 116 | 140 | 175 | 18 | 2 | 4-19 | 150 | 330 | 70 | 4-M8 | 17X17 |

|

80 |

3" | 203 | 80 | 126 | 150 | 185 | 18 | 2 | 8-19 | 165 | 330 | 102 | 4-M10 | 19X19 |

|

100 |

4" | 229 | 100 | 151 | 175 | 210 | 18 | 2 | 8-19 | 180 | 330 | 102 | 4-M10 | 19X19 |

|

125 |

5" | *356/300 | 125 | 182 | 210 | 250 | 20 | 2 | 8-23 | 170 | 25 | 102 | 4-M12 | 22X22 |

|

150 |

6" | *394/340 | 150 | 212 | 240 | 280 | 22 | 2 | 8-23 | 192 | 30 | 102 | 4-M12 | 27X27 |

| 200 | 8" | *457/450 | 200 | 262 | 290 | 330 | 22 | 2 | 12-23 | 234 | 35 | 102 | 4-M12 | 27X27 |

Unit:mm

Dimensions 20K |

||||||||||||||

|

Nominal Diameter |

L |

d |

D2 |

D1 |

D |

b |

f |

n-φd1 |

H |

W | A |

4-M |

KxK |

|

|

15 |

1/2" |

140 | 15 | 51 | 70 | 95 | 14 | 1 | 4-15 | 73 | 133 | 42 | 4-M5 | 9X9 |

|

20 |

3/4" | 152 | 20 | 56 | 75 | 100 | 16 | 1 | 4-15 | 76 | 133 | 42 | 4-M5 | 9X9 |

|

25 |

1" | 165 | 25 | 67 | 90 | 125 | 16 | 1 | 4-19 | 92 | 163 | 50 | 4-M6 | 11X11 |

|

32 |

1-1/4" | 178 | 32 | 76 | 100 | 135 | 18 | 2 | 4-19 | 95 | 163 | 50 | 4-M6 | 11X11 |

| 40 | 1-1/2" | 190 | 40 | 81 | 105 | 140 | 18 | 2 | 4-19 | 116 | 192 | 70 | 4-M8 | 14X14 |

|

50 |

2" | 216 | 50 | 96 | 120 | 155 | 18 | 2 | 8-19 | 123 | 192 | 70 | 4-M8 | 14X14 |

|

65 |

2-1/2" | 241 | 65 | 116 | 140 | 175 | 20 | 2 | 8-19 | 150 | 330 | 70 | 4-M8 | 17X17 |

|

80 |

3" | 282 | 80 | 132 | 160 | 200 | 22 | 2 | 8-23 | 165 | 330 | 102 | 4-M10 | 19X19 |

|

100 |

4" | 305 | 100 | 160 | 185 | 225 | 24 | 2 | 8-23 | 192 | 398 | 125 | 4-M12 | 22X22 |

|

125 |

5" | *381/356 | 125 | 195 | 225 | 270 | 26 | 2 | 8-25 | 170 | 25 | 102 | 4-M12 | 22X22 |

|

150 |

6" | *403/394 | 150 | 230 | 260 | 365 | 28 | 2 | 12-25 | 192 | 30 | 102 | 4-M12 | 27X27 |

| 200 | 8" | *502/457 | 200 | 275 | 305 | 350 | 30 | 2 | 12-25 | 234 | 35 | 102 | 4-M12 | 27X27 |

Packing & Delivery :

Packing Details

All by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details

Generally it is 5-10 days if the goods are in stock. or 15-30 days if the goods are OEM or not enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45 days.

X

X