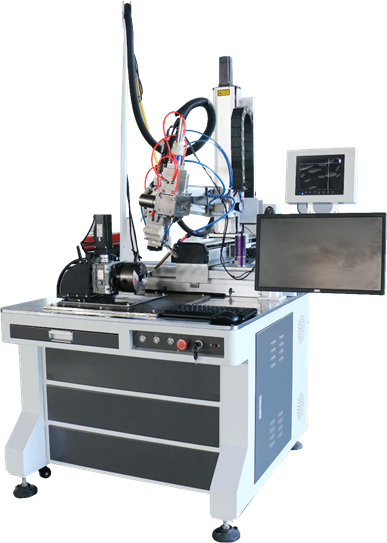

4-6 Axis Optical Fiber Laser Welding Machine, One-time forming welding for complex, special-shaped products, No deformation & blackening, Ideal for the products of high precision, large batch and high welding surface.

NO DENT/SOLID WELDING/NO TOOL MARKS

•Automatic Laser Welding Equipment

Advantages

01. Welding In A Multi-Dimensional Way

•Simultaneous 4-6 axis linkage & High positioning accuracy.

•Servo control; planar trajectory movement and rotating movement can be achieved.

•The welding head can rotate left and right, flexible & convenient.

•Any plane graphics composed of welding points, straight lines, circles, squares or straight lines and arcs, even complex welding structure parts can be realized beautiful welding formation.

•Water-cooling equipment ensures continuous 24-hour efficient. work ,meeting the needs of industrial mass production and processing.

02. Strong Welding Ability

•1000w-6000W laser are available, welding depth up to 10MM.

•Welding does not need to add any auxiliary materials, relying on the self-melting of the parent material, the firmness and subsequent processing are guaranteed.

03. Low-Energy Consumption

•High electro-optical conversion rate, low energy consumption, long-term use can save users a lot of processing costs.

04. Safer & Environmentally Friendly

•Compared with traditional argon arc welding which produces a large amount of welding dust and scum, laser welding is relatively environmentally friendly.

05. Beautiful Welding

•Small heat affected area during welding, no deformation of workpiece, no welding scar, firm welding, smooth and beautiful, the subsequent polishing process is reduced.

06. Low Labor Cost

•Automatic laser welding requires only ordinary operators, who can learn to work in 30 minutes.

•The efficiency and quality are several times better than manual welding, eliminating common welding problems that vary from person to person.

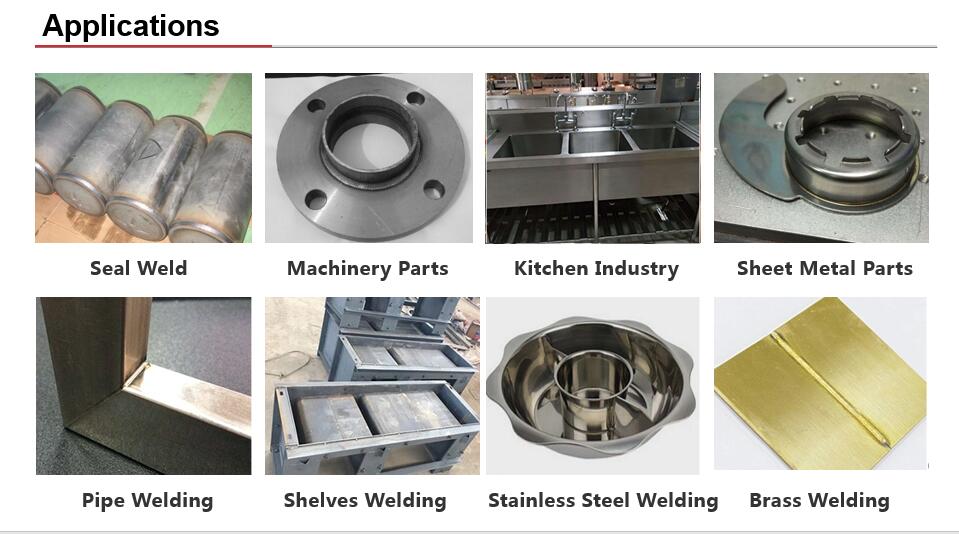

Suitable for seal weld, machinery parts, kitchen industry, sheet metal parts, pipe welding, shelves welding, stainless steel welding, brass welding and etc.

X

X