Ultrasonic Homogenizer For All Kinds Of Paint , Dye , Homogeneous Dispersion

| Minimum Order Quantity: |

1 Set |

| Price: |

|

| Packaging Details: |

Foam case |

| Delivery Time: |

In 7 Working Days |

| Payment Terms: |

T/T, WESTERN UNION |

| Supply Ability: |

100 Sets/Month |

Quick Detail:

Simple, low-cost design

Low operating costs

High efficiency

Low maintenance

Faster emulsification

Description:

Ultrasonic technique as a physical means and tools, can product in the reaction medium in a series of close to the extreme conditions, this energy can not only stimulate or promote many chemical reactions, accelerate the rate of a chemical reaction, and even may also change the direction of chemical reaction, generate a beat all effect and miracles.

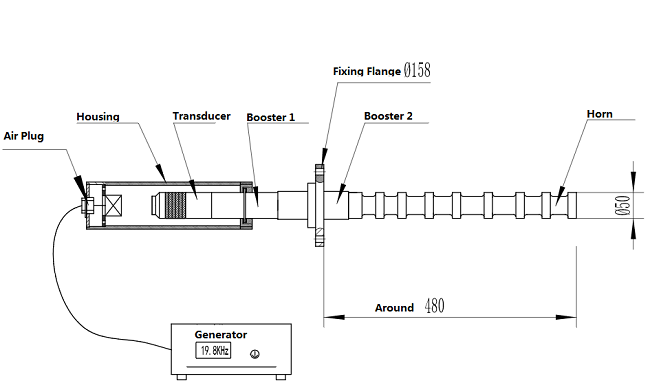

Industrial ultrasonic sonochemistry system is mainly used for largescale industrial production. It has big power,high efficiency, the advantages of large radiation area etc.. And can be customized according to customer needs.

Applications:

Ultrasonic in the biochemistry of the earliest applications should be used ultrasonic to crush the cell wall, to release its contents. Subsequent studies showed that, low intensity ultrasonic can promote the biochemical reaction process, such as ultrasonic irradiation can increase the speed of liquid nutrition growth of algal cells, making the cells to produce proteins increased 3 times.Energy density and cavitations bubble collapse of ultrasonic field energy density, energy density is enlarged trillion times, great concentration caused by energy; sound chemistry led to the phenomenon of extreme heat and pressure cavitations effect of luminescence, is unique in form of exchange of energy and substance of sonochemistry. Therefore, ultrasonic chemical extraction, biodiesel production, organic synthesis, governance microorganisms, degradation of toxic organic pollutants, the chemical reaction speed and yield, the catalytic efficiency, biological degradation, ultrasonic anti fouling, biological cell crushing, dispersion and agglomeration, and the chemical reaction is more and more important role.

Specifications:

| Model |

S-I20-1000 |

S-I20-1500 |

S-I20-2000 |

S-I20-3000 |

| Frequency |

20±0.5 KHz |

20±0.5 KHz |

20±0.5 KHz |

20±0.5 KHz |

| Power |

1000 W |

1500 W |

2000 W |

3000 W |

| Voltage |

220/110V |

220/110V |

220/110V |

220/110V |

| Temperature |

300 ℃ |

300 ℃ |

300 ℃ |

300 ℃ |

| Pressure |

35 MPa |

35 MPa |

35 MPa |

35 MPa |

| Intensity of sound |

20 W/cm² |

30 W/cm² |

40 W/cm² |

60 W/cm² |

| Max Capacity |

10 L/Min |

15 L/Min |

20 L/Min |

30 L/Min |

| Tip Head Material |

Titanium Alloy |

Titanium Alloy |

Titanium Alloy |

Titanium Alloy |

PS:If you need more power, we can install two or more device.

Competitive Advantage:

1. Save mixing time 20%~60%

2. Lower temps 30%~60%(30℃)

3. Less methanol 5%~30%

4. Less chemical (KOH) less 20%~50%

5. Total production cost save 15%~50%

6. Another benefit is the time of glycerol separation.This is also faster and one of the reasons for it is that less methanol is been used,so glycerol separation is faster.

X

X