ZXD Separated Type Water Electrolysis Hydrogen Generation Equipment/System

The hydrogen generation capacity of single equipment is up to 20Nm3/h-1500Nm3/h, and hydrogen generation’s layout is achieved by station.

The exterior of all stainless steel equipment has been polished which makes it good-looking.

The electrolyzer adopts bipolar filter pressing structure, and the insulation of sealing gasket is strong.

The structure of gas-liquid processor, whose process is simple, is frame combined, making the installation, operation and maintenance easier.

The silicon rectifier is adopted to replace the original silicon controlled rectifier, which can reduce the harmonic interference to the power grid, effectively eliminating the high-order harmonic pollution to the power grid, and reducing the reactive power loss.

Controlled by highly automatic microcomputer, the system is able to do remote centralized management. Human-machine intelligent interface makes the operation easy, safe and reliable.

The purity of the hydrogen generated can reach to 99.99%, Oxygen 99.2%

|

Product Details: 1. Equipment composition: main equipment, auxiliary equipment and electronic control equipment. 2. The main equipment composition: electrolyzer, auxiliary equipment integration framework. 3. Auxiliary equipment: water tank, alkali tank, supplementary water pump and gas decompression distribution frame, etc. 4. Electronic control equipment: rectifier cabinet, power distribution cabinet, etc. 5. Equipment features: equipment design is completely tailored to power plant users. Electrolyzer, gas-liquid treatment device, hydrogen drying frame are assembled into a frame which covers only a small area; purity of the hydrogen generated is high, while the moisture content is low; Automation degree is high, fully automatic one-button start and stop. |

|

Technical Specification

|

P/N |

ZXD-500 |

ZXD-550 |

ZXD-600 |

|

Hydrogen Production(m3/h) |

500 |

550 |

600 |

|

Oxygen Production(m3/h) |

250 |

275 |

300 |

|

Hydrogen Purity(V/V) |

≥99.99% |

≥99.99% |

≥99.99% |

|

Oxygen Purity(V/V) |

≥92.5% |

≥92.5% |

≥92.5% |

|

Operating load |

50%-100% |

50%-100% |

50%-100% |

|

Working Pressure(MPa) |

1.5~2.0 |

1.5~2.0 |

1.5~2.0 |

|

Hydrogen Moisture Content(g/m3) |

≤4 |

≤4 |

≤4 |

|

Hydrogen Alkalinity(mg/m3) |

≤1 |

≤1 |

≤1 |

|

Working Temperature(℃) |

85±5 |

85±5 |

85±5 |

|

Cooling water flow(m3/h) |

76 |

83 |

92 |

|

DC power consumption(kW·h/m3H2) |

≤4.3 |

≤4.3 |

≤4.3 |

|

External dimension of electrolyzer L×W×H (mm) |

4750x2325x2750 |

5160x2325x2750 |

5520x2325x2750 |

|

Electrolyzer Weight(kg) |

36600 |

38900 |

41400 |

|

Alkali concentration |

30% KOH |

30% KOH |

30% KOH |

Company Profile

Zhongxinda Electrolyzer Series Can Meet All Your Needs

As a manufacturer of high pressure alkaline electrolysis equipment, Zhongxinda offers the widest range of electrolytic cells on the market. In the pressure range of 1 to 30 bar, standard values being from 0.4 to 800 Nm3/h as, coupled with multi-megawatt solutions, our electrolyzer will meet all of your output pressure and purity needs; Our electrolyzer is suitable for a variety of applications (power, electronics, non-ferrous metal processing, food, etc.) as well as multi-megawatt solutions for mobility or heavy industry.

After-sales Service

We have a professional after-sales service team for hydrogen generation system with rich experience in hydrogen machine maintenance.According to the running state and environment of hydrogen production machine , we will help you optimize and upgrade the system, design plans suitable for the operation of the machine, improve the monitoring and detection for DCS and PLC, enhance the running safety and using cycle of hydrogen production equipment, so that reduce system failure caused by peripheral equipment (hydrogen compressor, dryer, PLC controller, etc.) and equipment failure or accident caused by personnel operation mistakes.

In view of the system shutdown caused by the fault of individual components for most users (such as system pressure imbalance and inaccurate measurement of the analyzer caused by the fault of pressure transmitter and ), we have stable detection methods and equipment maintenance plans for hydrogen production machine.

Certification

Zhongxinda has passed ISO9001 quality management system certification

Zhongxinda has passed the ISO45001 occupational health system certification

Zhongxinda has passed the ISO14001 occupational health system certification

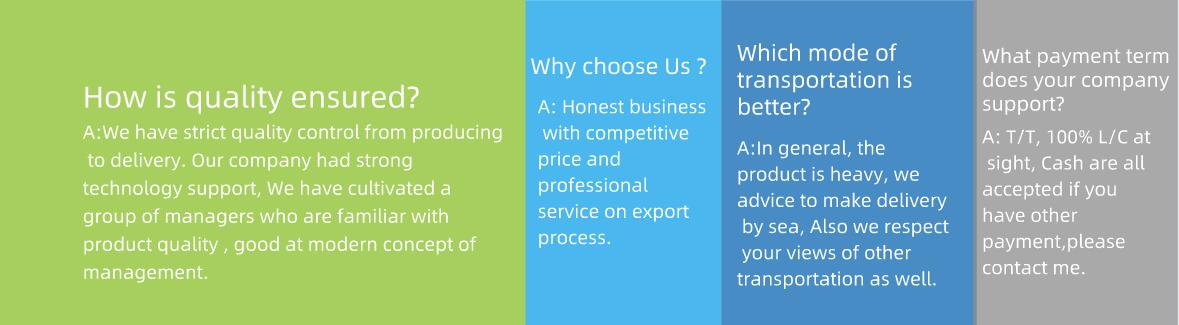

FAQ

X

X