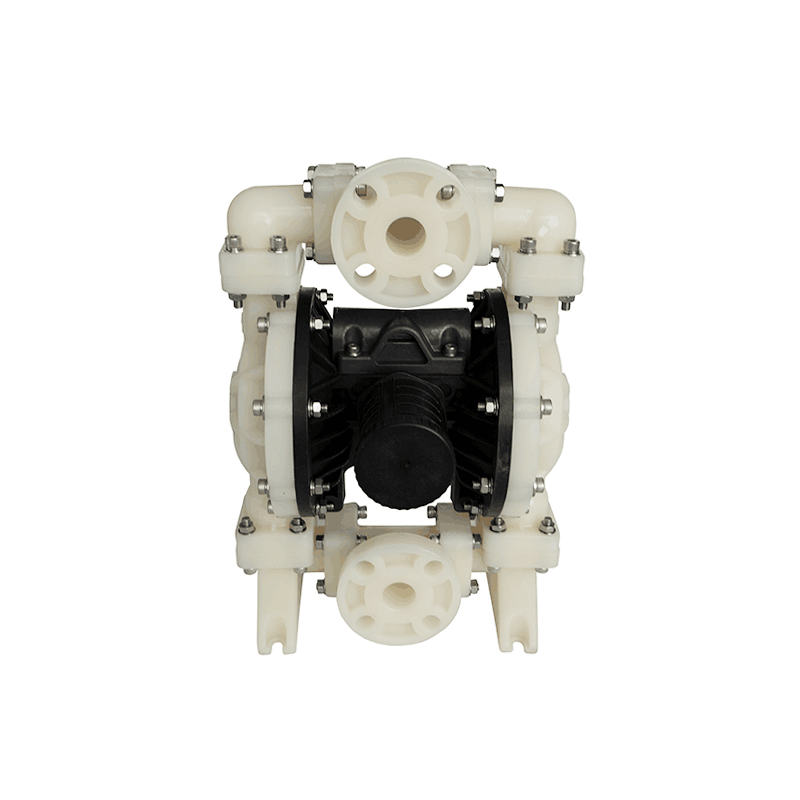

1 inch pp pneumatic diaphragm pump is also known as corrosion resistant engineering plastic AODD pump, Its flow pump body part is made of polypropylene, is not rust, no pollution, strong corrosion resistance of the 1 inch diaphragm pump for paints & solvents.

AOK25-PP Product Description:

AOK25 Pneumatic diaphragm pump is a new type of conveying machinery, which uses compressed air as the power source, and can suck up all kinds of liquids.

|

|

|

|

Performance parameter:

|

Model |

AOK-25PP |

|

|

Inlet/ Outlet size |

mm |

25 |

|

inch |

1 |

|

|

Flow Rate

|

m3/h |

9.42 |

|

L/min |

157 |

|

|

Head (m) |

84 |

|

|

Suction Stroke (m) |

8 |

|

|

Max. Particle Diameter (mm) |

4 |

|

|

Max.Air Pressure (kg/cm²) |

8.4 |

|

|

Max.Air Consumption (m³/min) |

1.12 |

|

|

Diaphragm |

Teflon, Santoprene, Buna-N, Viton, Hytrel, etc. |

|

|

Valve ball |

Teflon, Stainless steel, Santoprene, Hytrel, Viton, etc. |

|

|

Valve seat |

Santoprene, Teflon, Viton, Hytrel, etc. |

|

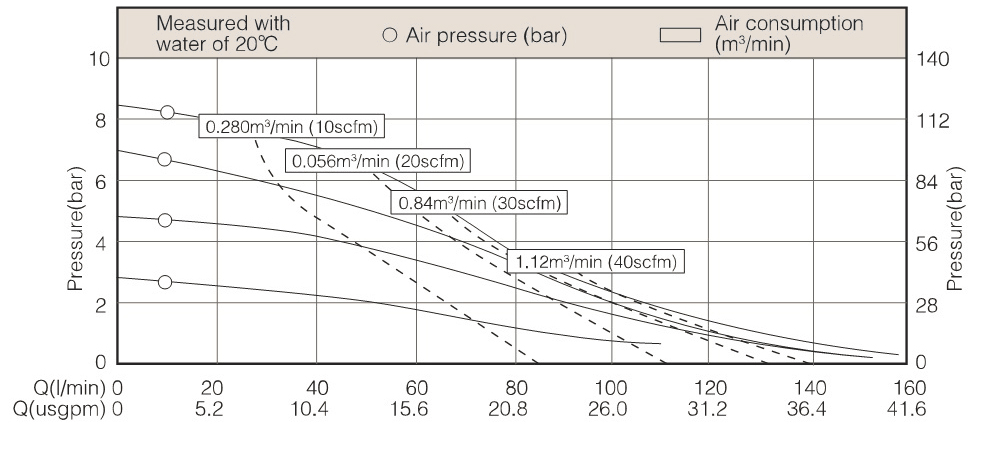

Performance curve:

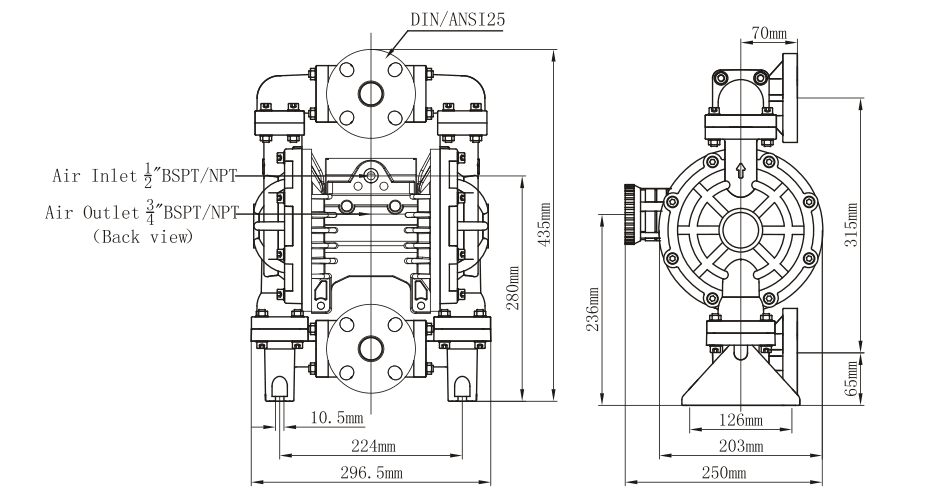

Installation size:

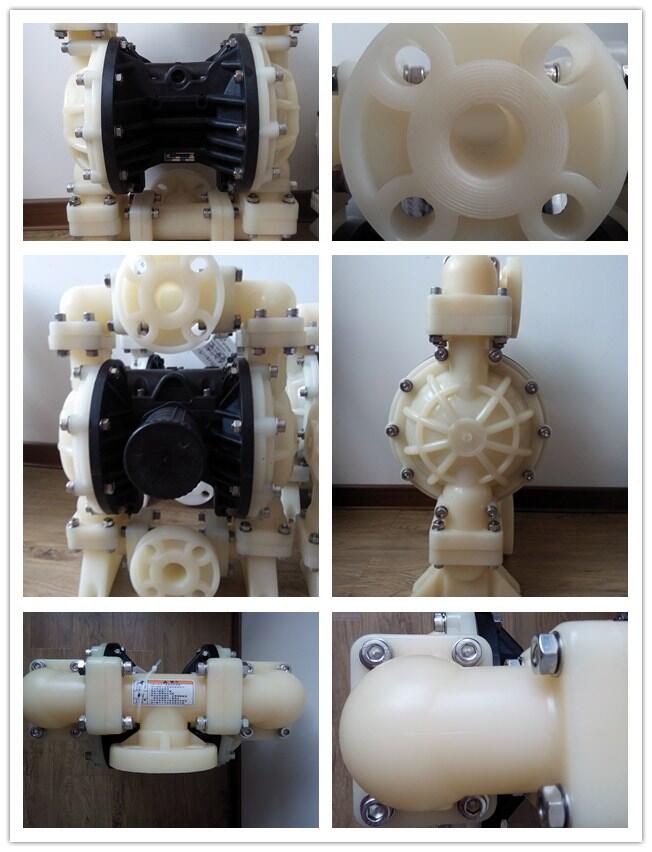

Details of the actual product on site: 100% real materials, quality assurance.

Pump Spare Parts :

Diaphragm:Diaphragm materials are Teflon (PTFE), Viton, Buna-n, Neoprene, Santoprene, EPDM, ect. The diaphragm is made of natural rubber, which has high chemical resistance and bending properties.

Valve ball and valve seat: The valve ball and valve seat materials are Teflon, Santoprene, Buna-N, EPDM, ect. It has a very low friction coefficient, excellent self-lubrication, good corrosion resistance, dimensional stability, and no deformation.

Product Usage:

Where can double diaphragm pumps be used?

1- The pump can suck the paint, pigment, glue and adhesive etc.

2- The pump can suck various glazed slurries of tile, porcelain, brick and chinaware etc.

3- The pump can suck various grinding materials, corrosive agent and clean the oil dirt etc.

4- The pump can suck various toxin and flammable or volatility liquid etc.

5- The pump can suck various cement slurry and mortar etc.

6- The pump can suck various strong acid, alkali and corrosive liquid etc.

7- It can be used as a front-step transmission device of the solid and liquid separation equipment.

8- Our pump can be used directly as a submersible pump, it uses air as the power source, and does not have the leakage and other security risks. This diaphragm pump has lower cost than submersible pump which is caused by the maintenance of motor.

X

X