CNC Milling Services

JY Machinery's CNC milling service is dedicated to tailoring prototypes and also end-use manufacturing components, from basic straight lines to complicated geometric shapes.

We support 3-axis, 4-axis, 5-axis milling as well as right-angle milling capabilities, generating more than 30 engineer plastics and also metal components, as well as composite insulation materials.

Our CNC milling services are developed to complement most of our various other manufacturing and finishing abilities, and also provide a fast as well as total complete solution for your project.

What is a CNC milling?

CNC milling is a specific sort of CNC machining. Milling is the procedure of getting rid of materials and developing various complex geometric shapes as well as component functions on the workpiece. Milling can do these processes to meet various manufacturing requirements. Milling utilizes a rotating cylindrical device, called a milling cutter, with the ability of reducing at different angles and also moving along different axes. It additionally has the capability to develop a wide range of shapes, slots, holes, as well as other necessary impressions, not just to supply accuracy and also repeatability, yet additionally flexibility.

What are the benefits of JY machinery's CNC milling service?

CNC Milling Video|JY Machinery

CNC Milling Materials

We work with a wide range of metal,plastic and composite materials.

Metal materials worked with include Aluminum, Stainless steel, Steel, brass, Copper, titanium and more.

Plastic materials worked with include polyurethane, ABS (weatherable and conductive), acrylic, polycarbonate, polyethylene (HDPE and HMWPE), PTFE, Delrin®, acetal, PVC and more.

Composite Materials worked with include G-10, FR-4, G-11, FR-5, Phenolic Cotton & Paper Laminated and more.

In addition to our stock list, we can provide you with customized raw material as required.

CNC Milling Tolerance

We define a basic dimensional tolerance of +-0.002" for CNC machined components. It is available to accomplish a tighter tolerance from our CNC routing, turning, 5-axis milling as well as 3-axis milling. If you need a tighter tolerance, please call us, as tighter tolerance might enhance the price of your order as well as need to be plainly specified upon getting.

Surface Finishes:

As Machined -Machining marks visible

Smooth Finish -Reduce the surface roughness and can be polished to glossy surface if request

Sandblasting -Cutter marks removed and scratched left behind by sand paper and light texture appearance

Brushing -Polishing the metal with grit resulting in a unidirectional satin finish

Anodizing -Corrosion Prevention and aesthetics

Power coating -Smooth and uniform surfaces and excellent corrosion resistance

Plating -Mirror like hard finish

See more Surface Finishing Capabilities here

Overview: What's CNC milling?

Why choose CNC milling?

CNC milling is perfect for producing angle channels, slots and shapes, chamfers, openings, contours as well as planes, amongst many other features. CNC milling eliminates a lot of materials promptly and with high accuracy, while producing a great surface finishing. Milling can be done on any kind of rigid material, although we primarily deal with plastics as well as metals. Of all offered CNC machining processes, milling is one of the most functional.

How many trypes of CNC milling machine?

The main distinction between a milling maker and other exploration machines is the capacity to cut at different angles as well as move along different axes. To this end, there are several types of milling devices, specified by the number of activity axes:

3-axis milling: This is one of the most typical sort of milling device. You can cut up and down in any type of instructions, yet things like balls need to be cut in half at once. This is because, despite 3 shafts, it is impossible to reduce from below.

4-axis milling: This type is a lot more complicated because they increase the ability to revolve the x-axis, comparable to a lathe.

5-axis milling: These machines combine rotation in the x and y axes. This is one of the most full milling maker you can have. It permits you to form bones, aerospace structures, auto versions, medical items, and also virtually anything you can envision.

What does CNC milling machine produce?

Normally speaking, when it involves prototypes, temporary manufacturing of complex parts and also the manufacture of precision components and also parts, CNC milling machines are really effective. But these powerful makers additionally offer many other advantages, specifically in controling most materials in a very efficient way. The hand-operated workshop still exists. With the cost of today's CNC machining, choosing the best CNC milling equipment can actually alter the production procedure in terms of time, accuracy and material quality.

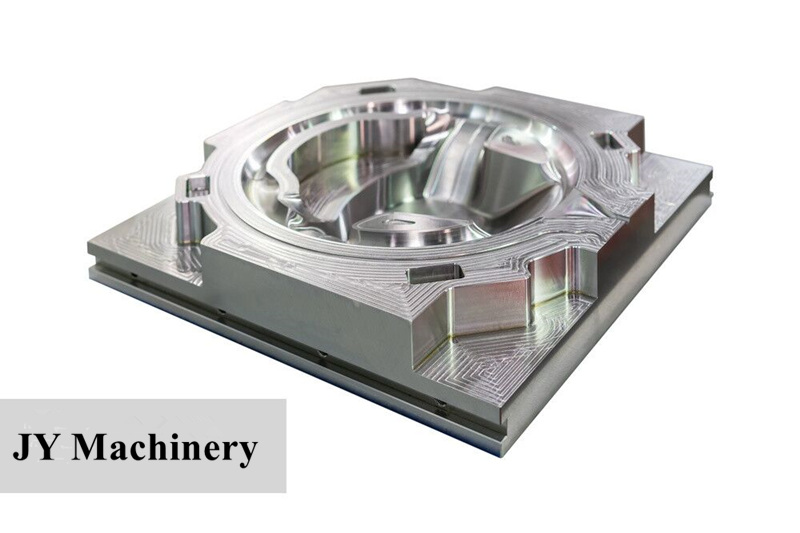

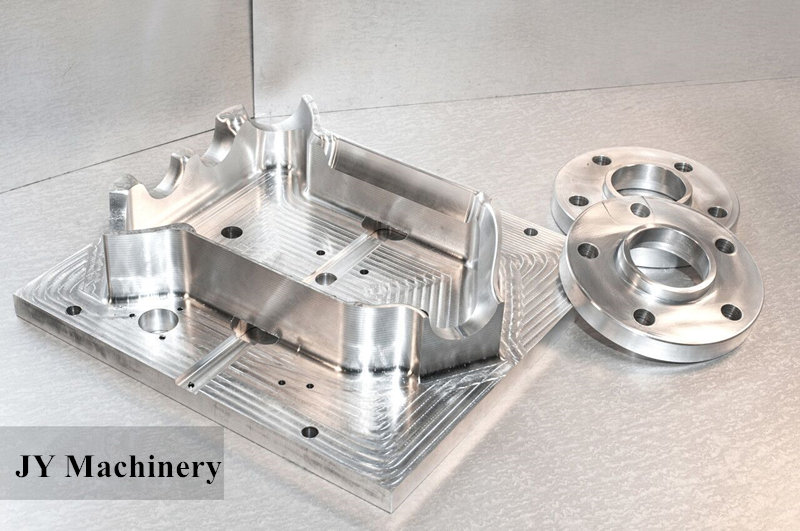

Products Show:

Get your CNC milling project started today

When you send out 3D CAD documents to us, JY Machinery will provide you with instant price, on-demand delivery time, as well as design for manufacturability comments for your customized CNC machining components on materials and also producing process, to make sure that the component can meet your expectations as well as budget plan demands. Get in touch with us today for a free quote!

X

X