W Valley Gutter Roll Forming Machine/W Valley Machine/Valley Flashing Roll Forming Machine/Fly Shearing Roof Valley Machine/Ridge Valley Roll Forming Machine/W Valley Trim Roll Former

is developed by Xiamen Reliance Industry co.ltd

Description:

W Valley Gutter Roll Forming Machine/W Valley Machine/Valley Flashing Roll Forming Machine/Fly Shearing Roof Valley Machine/Ridge Valley Roll Forming Machine/W Valley Trim Roll Former

The valley machine is to manufacturing various trims profiles. Steel roof valley flashings are produced on press brakes, folders or other hand operation brakes typically. The length of the produced valley is fixed and limited, Reliance w valley roll forming machine is capably to produce finished part from pre-cutting blanks in several seconds. That much improves the efficiency and save time. It can set various length order batches via program and control system, meanwhile are able to produce valley sheet automatically.

Reliance offer on-site installation, training and maintenance if have demand.

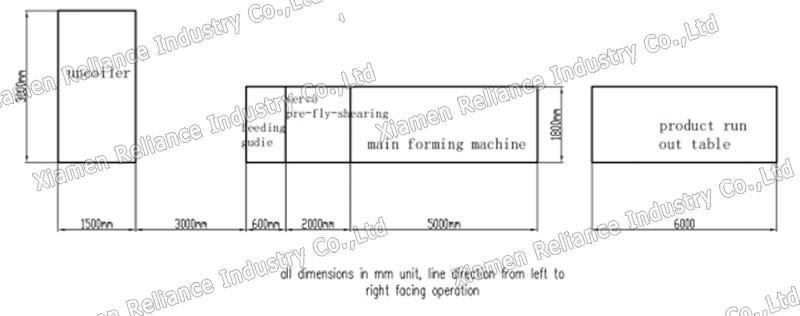

Draft Layout:

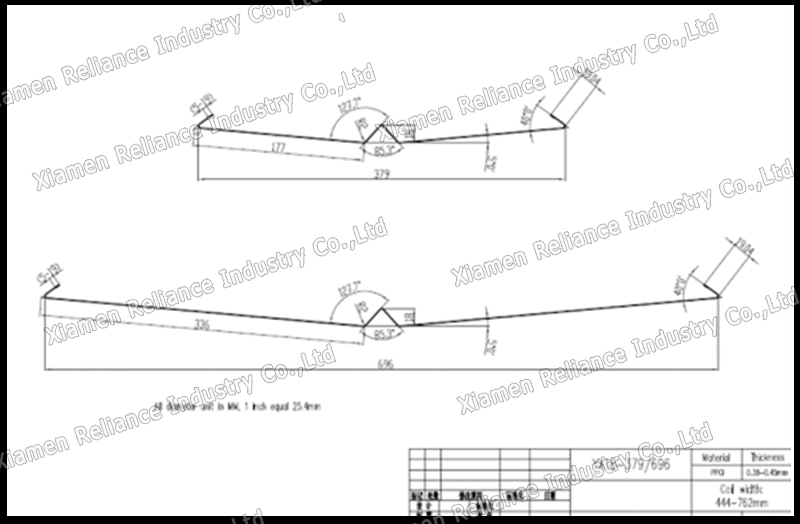

Profile:

The production line system includes:

5Ton*1000mm Hydraulic De-coiler with coil car

Power Feeding Section with Guide

Pre-fly shearing Section

No stop main roll forming machine

Electrical control system

Product run out table

Loading Photos:

X

X