Features

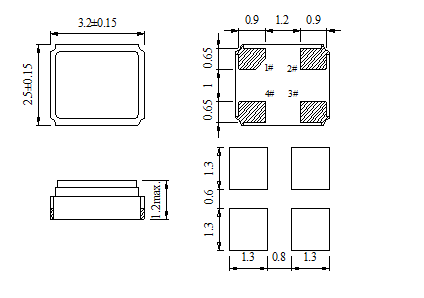

Miniature ceramic package, Size: 3.2 x 2.5 x 0.9mm

Low current consumption

Wide pulling range

CMOS output with Tri-state function CMOS

Seam sealed package with high reliability

IR Reflow capable

Low supply voltage available

Applications

Digital TV-tuner, Digital Video, DVD, DSC, etc.

Voltage Controlled Crystal Oscillators PVC3225

VCXO in ceramic seam seal SMD packages - HCMOS/ LVCMOS output

Electrical Parameters

|

No. |

Item |

Electrical Specification |

Remark |

||||

|

Min. |

Type |

Max. |

Units |

||||

|

1 |

Nominal Frequency |

10.000 |

MHz |

|

|||

|

2 |

Nominal Frequency Tolerance |

-1.0 |

|

+1.0 |

ppm |

Frequency at 25 C, 1 hour after reflow |

|

|

3 |

Frequency stability over temperature |

-0.5 |

|

+0.5 |

ppm |

Referenced to the frequency at 25℃. |

|

|

4 |

Temperature range |

-30 |

|

+85 |

℃ |

The operating temperature range over which the frequency stability is measured |

|

|

5 |

Frequency slope of perturbations |

-0.3 |

|

+0.3 |

ppm/ ℃ |

Minimum of 1 frequency reading every 2℃ , over -30℃ to +85℃ |

|

|

6 |

Supply voltage stability |

-0.3 |

|

+0.3 |

ppm |

Supply voltage varied ±5% at 25 ℃ |

|

|

7 |

Load sensitivity |

-0.2 |

|

+0.2 |

ppm |

±10% load change |

|

|

8 |

Aging |

-1.0 |

|

+1.0 |

Ppm |

first year at 25 ℃ |

|

|

9 |

Supply voltage |

|

3.3 |

|

v |

|

|

|

10 |

Current |

|

|

1.5 |

mA |

At maximum supply voltage |

|

|

11 |

Output waveform |

Clipped sine wave |

DC Coupled clipped sine wave |

||||

|

|

Output voltage level |

0.8 |

|

2 |

Vp-p |

|

|

|

12 |

Output load |

10Kohm//10Pf |

|

||||

|

13 |

Start Up time |

|

|

2 |

ms |

|

|

|

14 |

Pin 1, tri-state function |

pin 1=H or open......output active at pin 3 pin 1=L......high impedance at pin 3 |

|||||

|

15 |

Package type |

PVC3225 |

|||||

Dimensions

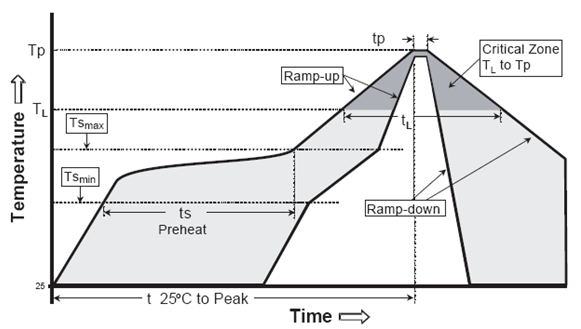

Reflow

| Profiles Feature | Pb-Free Assembly |

| Average Ramp-up Rate (Ts max to Tp) | 3℃/second max. |

|

Preheat ■ Temperature Min (Ts min) ■ Temperature Max (Ts max) ■ Time (ts min to ts max) |

125℃ 200℃ 60~180 seconds |

|

Time maintained above ■ Temperature (TL) ■ Time (tL) |

217℃ 60~150 seconds |

| Peak/Classification Temperature (Tp) | 260℃ |

|

Time within 5℃ of

actual Peak Temperature (tp) |

20~40 seconds |

| Ramp-down rate | 6℃/second max. |

| Time 25℃ to Peak Temperature | 8 minutes max. |

| Suggest reflow times | 3 Times max |

FAQ:

1. How does A-Crystal support you: Free samples , OEM, Reliability test report, Product return report (8D report), RoHS substances compliant, REACH substances compliant

2. What’s ACrystal’s performance Certificate? ISO 9001 quality management [9001 ISO 2015], ISO14001

3. How many Production patents ACrystal has: 16

4. Payment terms : T/T in advance

5. Which express service: DHL, UPS, TNT, FedEx

6. ACrystal’s monthly production capacity for 32.768 oscillators:1kk

7. What’s the MOQ/Standard packing quantity: 3k per reel ( acrystal 32.768)

8. Lead Time for the 32.768 khz clock oscillator: 3days-14days

9. ACrystal produces tuning fork crystals with 32.768 khz xtl.

10. Factory address: 17th Building, A District, Feiyue Technology Innovation Park, Jiaojiang, Taizhou, Zhejiang, China. ZIP:318014

11. What is the lead time for:

|

Series Product |

Quartz crystal size |

Lead Time |

|

HC49 Series |

HC-49SMD,HC-49S,HC-49U |

1-2 weeks |

|

SMD quartz Crystals |

2012/2016/2520/3225/5032/6035/7050/8045 |

1-4 weeks |

|

SMD crystal Oscillators |

2016/2520/3225/5032/7050 |

1-3 weeks |

|

TCXO |

2520/3225/5032 |

2-5 weeks |

|

SMD Watch/tuning fork Crystals |

PSX315/PSX415/PSX519/PMX145/PMX206/PMX206F/PMX206FA/PMX405/PMX406 |

1-2 weeks |

|

VCXO |

2520/3225/5032 |

2-5weeks |

|

TCVCXO |

2520/3225/5032 |

2-5weeks |

|

DIP Watch/tuning fork Crystals |

DT206/DT308 |

1-2weeks |

|

ZTA/ZTT Series |

ZTTCC/ZTACC/ |

1-2weeks |

12.Free crystal samples and shipment fee ?

We provide you 20pcs free quartz crystals samples [no free samples for oscillators and TCXO,VCXO, and VCTCXO]. Customers to pay only the shipping fees.

13. What basic information to provide when ordering a crystal?

|

SMD or DIP |

Crystal package size[mm] |

2pads ,3pads or 4pads... |

|

Frequency: GHz,MHz or KHz |

frequency tolerance[ppm] |

frequency charactristics over temperature[ppm] |

|

load capacitance[pF] |

operating temperature[℃] |

resistance(ESR)[Ω/㏀] |

|

Supply Voltage[V] |

Output type |

application |

14. Main sources of ACrystal component parts

|

Crystal Bar |

China |

|

Base |

NEC (Japan) |

|

Outer covering |

NEC (Japan) |

|

Resin |

HENKEL (Germany) |

|

High-temperature crystal |

KDS (Japan)

|

|

Equipment Name |

Manufacturer |

Quantity |

Purpose |

|

Coaters |

Korea |

3 |

put the silver on the tuning fork tips |

|

Auto Dispensing |

Japan |

5 |

Stick the crystal on base |

|

Fine tuning |

China |

32 |

Frequency modulation and control |

|

Welding |

China |

12 |

To weld the outer covering and base |

|

Laser Marking |

China |

3 |

Marking on the outer covering |

|

250B |

USA |

3 |

Test the frequency |

|

High and low temperature testing |

USA |

3 |

High and low temperature testing |

|

Automatic testing |

China |

8 |

Test the crystal |

|

Insulated resistance tester

|

China |

6 |

Test the crystal |

16. PMX145/206/308SMD Production & Test Equipment

|

NO. |

Use process |

Equipment Name |

Model |

manufacturer |

Unit |

Quantity |

|

1 |

Pin bending |

Auto pin bending |

DT206/308 |

CHINA |

PCS |

2 |

|

2 |

Pin cutting |

Auto pin cutting |

DT308/206 |

CHINA |

PCS |

6 |

|

3 |

Spot welding |

spot welding |

SW-Ⅱ |

CHINA |

PCS |

16 |

|

4 |

Auto spot welding |

SW-300(refit ) |

CHINA |

PCS |

2 |

|

|

5 |

Plastic package |

HF Preheat machine |

HDP-320 |

CHINA |

PCS |

4 |

|

6 |

hydraulic machine |

MP-125 |

CHINA |

PCS |

4 |

|

|

7 |

Orthopedic |

Hydraulic Presses |

YN-12 |

CHINA |

PCS |

10 |

|

8 |

Marking |

Laser Marking |

YAG-M-50 |

CHINA |

PCS |

5 |

|

9 |

Testing equipment |

Clock Tester |

QWA-5A |

CHINA TW |

PCS |

1 |

|

10 |

Crystal impedance meter |

FT-327B |

CHINA |

PCS |

20 |

|

|

11 |

network analyzer |

250B |

USA |

PCS |

3 |

|

|

12 |

Frequency meter |

FT-100T |

CHINA |

PCS |

15 |

|

|

13 |

Automatic testing |

BJ-308/206 |

CHINA |

PCS |

20 |

|

|

14 |

crystal calibration |

GY3020 |

CHINA TW |

PCS |

1 |

|

|

15 |

Crystal impedance meter |

CZ-5C |

CHINA TW |

PCS |

1 |

|

|

16 |

Spectrometer |

ZDX8600 |

CHINA TW |

PCS |

1 |

|

|

17 |

Reflow |

T1000 |

CHINA |

PCS |

1 |

|

|

18 |

Insulated resistance tester |

TH3681A |

CHINA TW |

PCS |

1 |

|

|

19 |

Incubator |

4310 |

USA |

PCS |

4 |

|

|

20 |

Taping |

Auto Taping |

PMX206 |

CHINA |

PCS |

9 |

17. Quality Management

Ø A-crystal supports its customer base through the pursuit of continuous quality improvement.

Ø World-Class leading product designs.

Ø ISO-9001 certified production and Quality management

Ø Reliability testing for all products to ensure quality stability.

Ø Strict quality evaluation of all raw material suppliers

Ø Customers satisfaction feedback program for quality assurance

Ø Complete sales & after-sales quality service and customer care

Ø Regular employee trainings to achieve continuous quality improvement.

Management participation programs to promote commitment to highest quality standards and customer focus.

18. how’s a-crystal’s Customer Care : returns process

19. how to see acrystal production line radio on tube :https://www.acrystals.com/about-us_d1

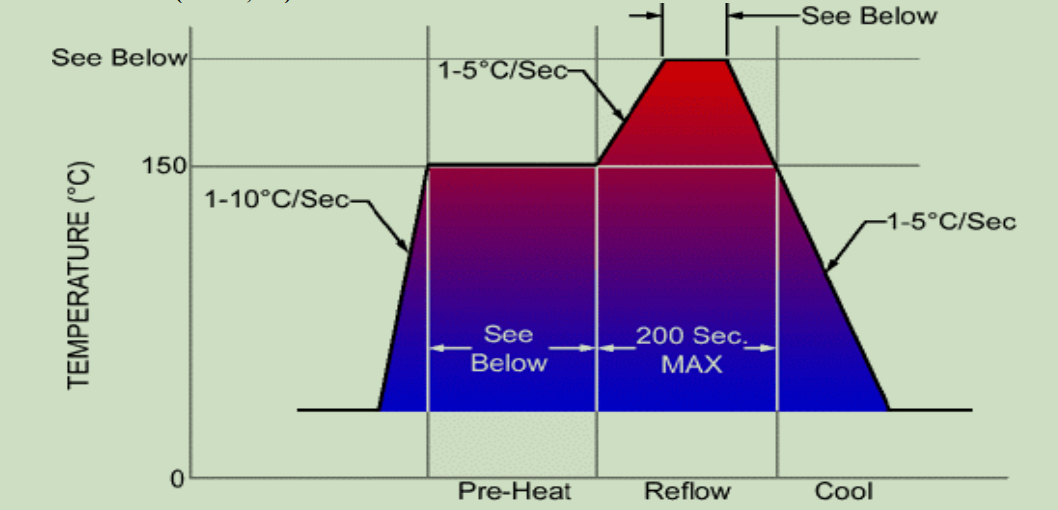

20. how to attach a tuning fork to PCB/Acrystal recommended Solder Reflow?

Soldering Characteristics

A variety of methods can be used to solder A-Crystal products to PCB and substrates

Ø Wave or Dual Wave

Ø Hot Air or Convection Flow

Ø Vapor Phase Reflow

Ø Infrared Reflow

Ø Bubble Solder Immersion

Ø Tohers (Laser,etc)

|

Model |

Pre-heating time |

Reflow Temperature |

Reflow time |

|

SMD Tuning fork 01(lead free) |

60-120 Seconds |

230℃ Max |

10 Seconds Max |

|

SMD Tuning fork 02(no lead free for solder, but ROHS compliant) |

30-60 Seconds |

260℃ Max |

10 Seconds Max |

|

HC-49U |

30-60 Seconds |

250℃ Max |

10 Seconds Max |

|

HC-49S series |

30-60 Seconds |

250℃ Max |

10 Seconds Max |

|

HC-49SM series |

30-60 Seconds |

250℃ Max |

10 Seconds Max |

|

UM series |

30-60 Seconds |

250℃ Max |

10 Seconds Max |

|

SMD crystal units |

30-60 Seconds |

250℃ Max |

10 Seconds Max |

|

Clock Oscillator |

30-60 Seconds |

250℃ Max |

5 Seconds Max |

|

VCXO |

30-60 Seconds |

250℃ Max |

5 Seconds Max |

|

SMD oscillator |

30-60 Seconds |

260℃ Max |

10 Seconds Max |

|

Ceramic Resonator |

30-60 Seconds |

225℃ Max |

10 Seconds Max |

|

Ceramic Filter |

30-60 Seconds |

225℃ Max |

10 Seconds Max |

21. What’s the pictures of the Acrystal time quartz watch XTAL/ timing oscillator/tuning fork resonator?

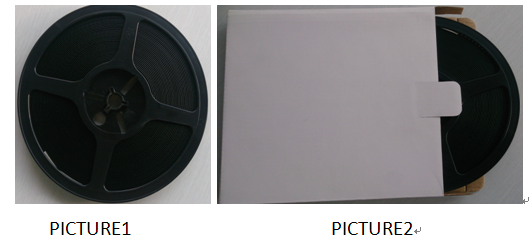

22. Package:

Package is made of corrugated paper with thickness of 0.8cm.

Each Package contains 10 inner boxes, each box has 1 plastic reel

Each reel has 3000 pieces of Crystal Resonators

Therefore Total package contains 30,000 pieces of crystal resonators.

Large package contains 20 inner boxes (60, 000 pieces of crystal resonators)

23. Why ACrystal?

Pricing: Highly competitive pricing

Quality: ISO 9001 certified quality system and knowledgeable quality assurance team.

Delivery : Short lead-time for standard products and on time delivery for customized products.

Service: Comprehensive skilled technical support

X

X