Ceramic honeycomb substrate is a new kind of catalyst monolith, which is widely used in automobile emissions purifying system and industrial exhaust gas treatment system. After coated with catalysts, this product is applied in catalytic converter of diesel or gasoline vehicle to catalyze, convert and purify the exhaust, making vehicle exhaust reaching standards of Euro Ⅱ and Euro Ⅵ

Monolithic ceramic cordierite material catalyst honeycomb substrate

Product details:

|

Items |

Parameters |

|

|

Chemical Composition (%) |

SiO2 |

49~51 |

|

|

Al2O3 |

33~35 |

|

|

MgO |

13~14 |

|

Wall Thickness |

100 CPSI |

0.43 |

|

|

200 CPSI |

0.32 |

|

|

300 CPSI |

0.30 |

|

|

400 CPSI |

0.18 |

|

|

600 CPSI |

0.15 |

|

Compressive Strength (MPa) |

A-Cut (Parallel Channels) |

≥16 |

|

|

B-Cut (Vertical Channels) |

≥3 |

|

Water Absorption(%) |

25±2 |

|

|

Coefficient of Thermal Expansion (10-6/K-1) |

0.8~2.0 |

|

|

Maximum Operating Temperature (°C) |

≥1370 |

|

|

Bulk Density (Kg/L) |

0.43~0.75 |

|

| Available Common Used Dimensions | |||

| Shape | Hole density (hole/inch2) | Size (mm) | Size (inch) |

| Round | 300 CPSI | φ101.6 X152.4 | 4X6 |

| Round | 300 CPSI | φ118.4 X100 | 4. 66X3. 94 |

| Round | 300 CPSI | φ118.4 X152.4 | 4. 66X6 |

| Round | 300 CPSI | φ150 xlOO | 5.9X3. 94 |

| Round | 300 CPSI | φ170 xlOO | 6. 69X3. 94 |

| Round | 300 CPSI | φ190 xlOO | 7. 48X3. 94 |

| Round | 300 CPSI | φ210 xl30 | 8. 26X5. 12 |

| Round | 300 CPSI | φ240 x76.2 | 9. 45X3 |

| Round | 300 CPSI | φ240 xlOO | 9. 45X3. 94 |

| Oval | 300 CPSI | φ120.6 x 80 x 152.4 | 4. 75X3. 15X6 |

| Oval | 300 CPSI | φ144.8 x 81.3 x 152.4 | 5.7X3.2X6 |

| Oval | 300 CPSI | φ169.7 x 80. 8 x 115 | 6. 68X3. 18X4. 52 |

| Round | 400 CPSI | φ150 xlOO | 5.9X3. 94 |

| Round | 400 CPSI | φ144 x 152.4 | 5. 66X6 |

| Round | 400 CPSI | φ118.4 x 152.4 | 4. 66X6 |

| Round | 400 CPSI | φ115.4 x 152.4 | 4. 54X6 |

| Round | 400 CPSI | φ106 x 100 | 4. 17X3. 94 |

| Round | 400 CPSI | φ103 x 100 | 4. 05X3. 94 |

| Round | 400 CPSI | φ101.6 x 152.4 | 4X6 |

| Round | 400 CPSI | φ100 x 100 | 3. 94X3. 94 |

| Round | 400 CPSI | φ93 x 152.4 | 3. 66X6 |

| Round | 400 CPSI | φ83 x 152.4 | 3. 26X6 |

| Round | 400 CPSI | φ80 x 100 | 3. 15X3. 94 |

| Round | 400 CPSI | φ76.2X50 | 3X1.97 |

| Round | 400 CPSI | φ60X85 | 2. 36X3. 34 |

| Oval | 400 CPSI | φ169 x 85. 7 x 115 | 6. 65 x 3. 37 x 4. 52 |

| Oval | 400 CPSI | φ169 x 80. 8 x 115 | 6. 65 x 3. 18 x 4. 52 |

| Oval | 400 CPSI | φ148 x 84 x 152.4 | 5. 82 x 3. 3 x 6 |

| Oval | 400 CPSI | φ144.8 x 81.3 x 152.4 | 5. 7 x 3. 2 x 6 |

| Oval | 400 CPSI | φ127 x 63. 5 x 152.4 | 5 x 2. 5 x 6 |

| Oval | 400 CPSI | φ93 x 61 x 90 | 3. 66 x2. 4 x 3. 54 |

| Oval | 400 CPSI | φ120.6 x 80 x 152.4 | 4. 75 x 3. 15 x6 |

| Oval | 400 CPSI | φ 143 x 98 x 152.4 | 5. 63 x 3. 86 x 6 |

| Oval | 400 CPSI | φ147 x 95 x 152.4 | 5. 78 x 3. 74 x 6 |

| Oval | 400 CPSI | φ177.8 x 114.3 x 170 | 7 x 4. 5 x 6. 7 |

| Irregular | 400 CPSI | 144 x 84 x 75 | 5. 67 x 3. 3x 2. 95 |

| Irregular | 400 CPSI | 114 x 105 x 115 | 4. 49 x 4. 13 x 4. 52 |

| Irregular | 400 CPSI | 112.2 x 92 x 115 | 4. 42 x 3. 62 x 4. 52 |

| Irregular | 400 CPSI | 119.5 x 99. 5 x 115 | 4. 7 x3. 92 x 4. 52 |

| Irregular | 400 CPSI | 120. 2 x 108. 2 x 75 | 4. 73 x 4. 26 x 2. 95 |

| Irregular | 400 CPSI | 122. 3 x 104. 4 x 80 | 4.81 x 4. 11 x 3. 15 |

Advantage:

1.High specific surface area: ensure exhaust gas could contact weigh catalyst enough.

2.Stable water absorption: guarantee catalyst could be firmly and evenly coated on the surface of substrate, so it's no waste for too thick coating.

3.Fast in temperature rising: after starting up engine, the temperature of substrate could reach the active temperature of catalyst in the shortest time.

4.Low exhaust resistance: ask exhaust resistance of substrate to engine low, so that it won't affect the performance of engine.

5.High intensity substrates work in bumpy cars, so the intensity of substrates must be too high to be destroyed.

6.Perfect assembly: substrates are parts of exhaust, perfect appearance and exact dimension could ensure assembly perfect.

Products show:

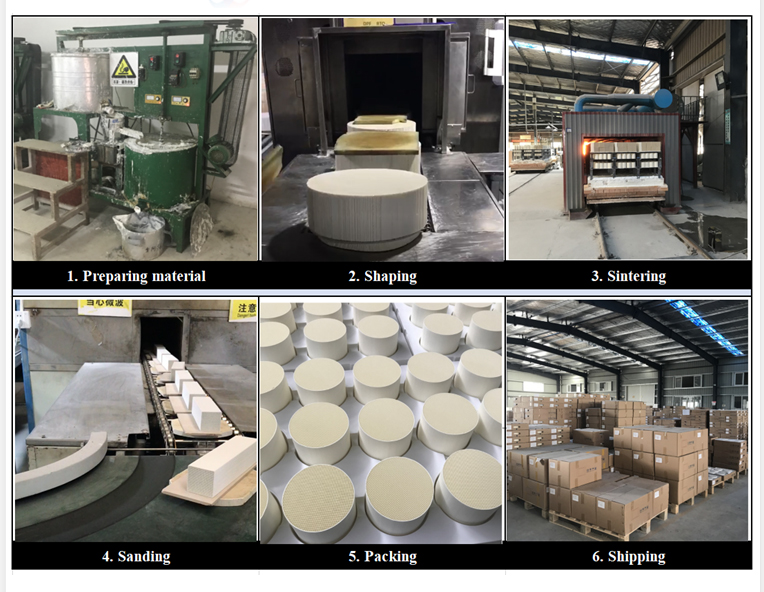

Production process:

Packing and shipping:

FAQ:

Q1. Are you a factory or trading company

A: We are a factory, specialize in catalyst coating.

Q2. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. We also pack them according your request.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q4. Can I etch the logo on the products?

A: Yes, Etching logo are available.

Q5. How about your delivery time?

A: Generally, it will take 7 to 20 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q6. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

X

X