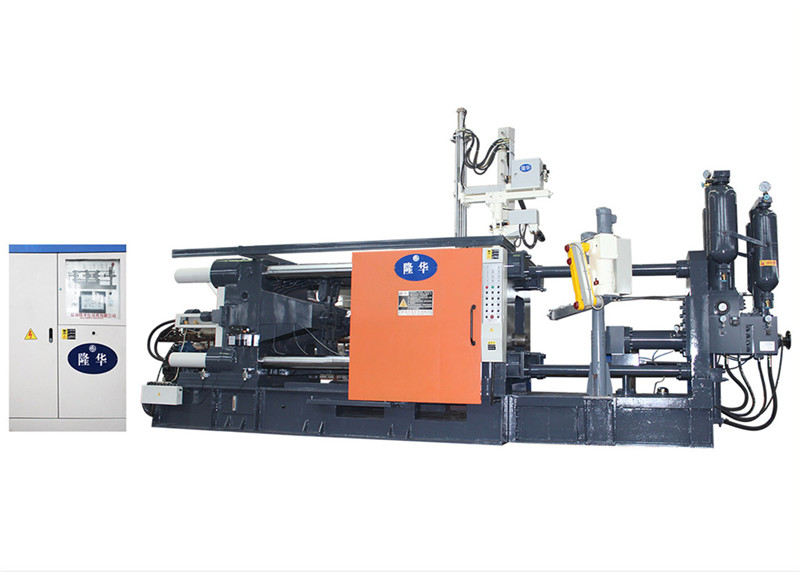

Longhua die casting machine die casting machine for aluminium cookwares, high efficiency and easy automation.

Product Item:

Intelligent vacuum die casting machines for manufacturing aluminium cookwares(LH-800T)

According to the requirements of yield, production process, variety and size, the types and models of die casting machines,production efficiency and load rate of equipment should be coordinated and reasonably configured.

Do not use large machines with small or large ones, but use fine machines with large ones to ensure the safe operation of die casting machine sand give full play to their efficiency.

LH SERIES OF STANDARD PARAMETER TABLE (LH-800 T)

|

ITEMS |

UNIT |

SPECIFICATION |

|

HYDRAULIC WORKING PRESSURE |

MPA |

14 |

|

CLAMPING FORCE |

KN |

8000 |

|

SPACE BETWEEN TIE BARS |

MM |

810*810 |

|

TIE BAR DIAMETER |

MM |

¢170 |

|

DIE OPENING STROKE |

MM |

750 |

|

INJECTION FORCE(INTENSIFY) |

KN |

680 |

|

PLUNGER LAUNCH DISTANCE |

MM |

280 |

|

INJECTION POSITION |

MM |

0 -- 250 |

|

PLUNGER DIAMETER |

MM |

¢80----¢100 |

|

INJECTION STROKE |

MM |

720 |

|

CASTING PRESSURE (INTENSIFY) |

MPA |

153/78/57 |

|

CASTING FIANGE PROTRUSION |

MM |

20 |

|

CASTING FIANGE DIAMETER |

MM |

180 |

|

MAX CASTING AREA UNDER 40MPA |

CM2 |

1900 |

|

LNJECTION WEIGHT(AL) |

KG |

13 |

|

DIE HEIGHT(MIN--MAX) |

MM |

350~900 |

|

EJECTOR FORCE |

KN |

315 |

|

EJECTOR STROKE |

MM |

200 |

|

MOTOR CAPACITY |

KW |

30 |

|

MACHINE DIMENSIONS (L*W*H) |

M |

9*2.2*3.1 |

|

REFERENTIAL MACHINE WEIGHT FOR UPLIFTING |

T |

35 |

|

OIL TANK CAPACITY |

L |

1500 |

PS:WE RESERVE THE RIGHT TO MAKE ANY TECHNICAL IMPROVEMENT WITHOUT FURTHER NOTICE

Safe operation rules for aluminum alloy die casting machine

1.Aluminum alloy die casting machine before starting up, the first need to put the pressure relief valve handle in the pressure relief position, until the normal operation of the motor, and then release the pressure relief valve handle.

2.Aluminum alloy die casting machine must heat the model to the specified temperature before shooting, and then can be pressed into the metal solution.

3. Protective baffle should be used at the contact point of mold parting surface and gate. Operators must wear protective glasses.The operator shall not stand on the opposite side of the parting surface contact.Prevent metal liquid spatter injury.

4. Do not bring naked fire near the fuel tank.Water cooling shall be applied when the tank temperature exceeds the specified operating temperature of the equipment.

5. Tools should be used when removing castings and casting risers from die casting molds.After removing the casting, the metal residue adhering to the mold and the air hole should be removed in time.

6. When the work is finished, the oil pump must be stopped and all valves closed.If the insulation furnace is used for the insulation of metal liquid, turn off the power supply and stop the ventilation equipment on the insulation furnace.

X

X