Water electrolysis hydrogen production equipment / drying integrated device in power plant

Product Specification

Equipment Composition: Main equipment, Auxiliary equipment and Electric control equipment.

Main equipment composition: Electrolyser,accessory equipment integrated framework

Auxiliary equipment composition: Water tank, alkali tank, make-up water pump and gas decompression distribution Framework,etc

Electronic control equipment composition: Rectifier cabinet,Power Distribution Cabinet,etc

Equipment Characteristics: The equipment design can be customized according to the users of the power plant. The electrolytic , gas-liquid treatment device and hydrogen drying frame are assembled into a frame, which covers a small area. The product has high hydrogen purity, low moisture content and high degree of automation, which fully realizes the automatic one button start-up and stop.

The equipment includes integrated hydrogen production unit, hydrogen decompression distribution panel, control cabinet, rectifier cabinet, make-up pump, raw water tank, alkali liquor tank and analytical instrument.

Pneumatic unit, combined instrument control, electric control, PLC control, fieldbus control.

Technical Specification

Technical Specification

|

P/N |

ZXD-275 |

ZXD-300 |

ZXD-350 |

|

Hydrogen Production(m3/h) |

275 |

300 |

350 |

|

Oxygen Production(m3/h) |

137.5 |

150 |

175 |

|

Hydrogen Purity(V/V) |

≥99.99% |

≥99.99% |

≥99.99% |

|

Oxygen Purity(V/V) |

≥92.5% |

≥92.5% |

≥92.5% |

|

Operating load |

50%-100% |

50%-100% |

50%-100% |

|

Working Pressure(MPa) |

1.5~2.0 |

1.5~2.0 |

1.5~2.0 |

|

Hydrogen Moisture Content(g/m3) |

≤4 |

≤4 |

≤4 |

|

Hydrogen Alkalinity(mg/m3) |

≤1 |

≤1 |

≤1 |

|

Working Temperature(℃) |

85±5 |

85±5 |

85±5 |

|

Cooling water flow(m3/h) |

43 |

48 |

55 |

|

DC power consumption(kW·h/m3H2) |

≤4.3 |

≤4.3 |

≤4.3 |

|

External dimension of electrolyzer L×W×H (mm) |

4270x1885x2200 |

4570x1885x2200 |

2680x2325x2750 |

|

Electrolyzer Weight(kg) |

26300 |

27600 |

30000 |

|

Alkali concentration |

30% KOH |

30% KOH |

30% KOH |

|

Circulation quantity of alkali liquor(m3/h) |

16~19 |

17~20 |

18~25 |

Company Profile

Company Profile

zxdh2 is the process of converting surplus renewable energy into hydrogen gas by rapid response electrolysis and its subsequent injection into the gas distribution network.

We are currently engaged in several projects aimed at deployment of our technology and products in existing and emerging markets.

zxdh2 has a Business Development team that is resourced and structured to be able to efficiently and effectively liaise with customers in key territories across the world, and to be able to communicate effectively with customers from a range of key industries and project applications.

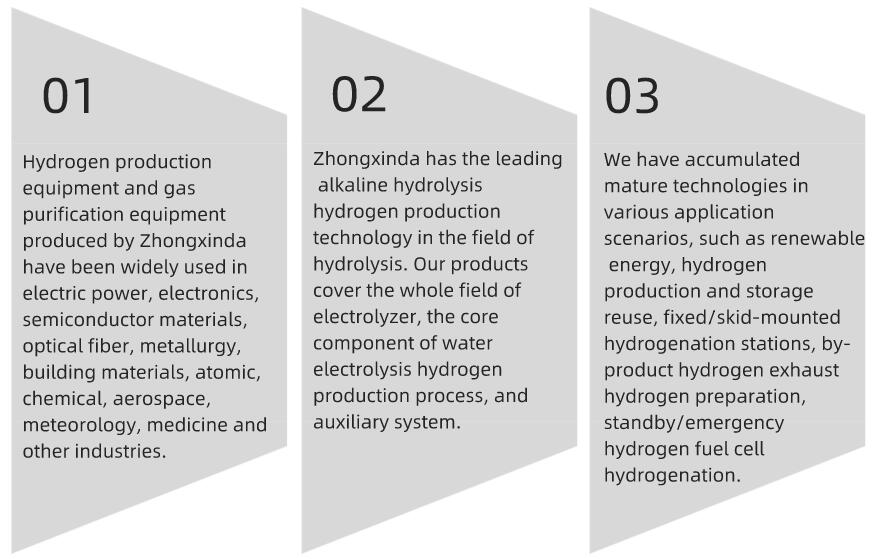

Our Advantages

Our Advantages

Overhaul and Reconstruction

Overhaul and Reconstruction

Professional engineers understand the operation status of your hydrogen production system, and the performance indicators of core components, and propose solutions to ensure the safe operation of your hydrogen production equipment.

In order to ensure the construction period of the maintenance and reconstruction project.

The company has a variety of brands of electrolyzers in stock throughout the year. "Excellent service, professional skills, quick response" is our consistent working attitude.

Certification

Certification

Zhongxinda has passed ISO9001 quality management system certification

Zhongxinda has passed the ISO45001 occupational health system certification

Zhongxinda has passed the ISO14001 occupational health system certification

FAQ

FAQ

Q1: Why choose Us ?

A:To provide our customers services in the supply of quality

Q2: How is quality ensured?

A:We have strict quality control from producing to delivery. Our company had strong technology support, We have cultivated a group of managers who are familiar with product quality , good at modern concept of management.

Q3:Which mode of transport would be better?

A:In general, the product is heavy, we advice to make delivery by sea, Also we respect your views of other transportation as well.

Q4:What kind of payment does your company support?

A: T/T, 100% L/C at sight, Cash are all accepted if you have other payment,please contact me.

X

X