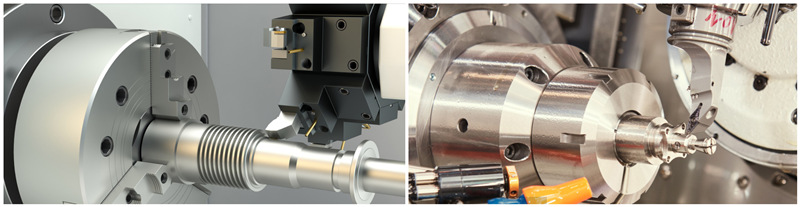

JY Machinery offer CNC turning capabilities such as facing, threading, drilling, boring, reaming and taper turning offered.

CNC Turning Service

At JY Machinery, we can supply the most affordable and capable resources consist of CNC turning, which involves making use of a revolving metal pole and also a cutting tool to eliminate surface area materials as well as produce a completed part or component.Our on-demand production platform can provide top quality metal or plastic turned components for fast prototyping or low-to-high volume manufacturing runs.you can obtain CNC transformed prototypes as well as manufacturing components less than 50% time in comparsion to our competitors while keeping the anticipated qulaity you are worthy of.

What's CNC Turning?

CNC turning is a subtractive production procedure that turns a metal/plastic pole while a reducing tool is held versus the stock to get rid of material as well as develop round shapes and features like rings, grooves, slots, shapes, spans, internal bores and also strings. while leaving an excellent surface finish that occasionally requires no post-processing.

Turning procedures on a CNC turret can be very effecient for high quantity runs. The addition of a bar feeder can aid automate the procedure and lessen manual activity by the machinist.

What Are The Advantages of JY Machinery's CNC Turning Service?

CNC Turning Video|JY Machinery

CNC Turning Materials

We work with a wide range of metal,plastic and composite materials.

In addition to our stock list, we can provide you with customized raw material as required.

CNC Turning Tolerance

We define a basic dimensional tolerance of +-0.002" for CNC machined components. It is available to accomplish a tighter tolerance from our CNC routing, turning, 5-axis milling as well as 3-axis milling. If you need a tighter tolerance, please call us, as tighter tolerance might enhance the price of your order as well as need to be plainly specified upon getting.

CNC Turning Finishes

Overview:CNC Turning Service

1. What's difference between CNC Turning and CNC Milling?

CNC milling and CNC turning both enable customer to create high accuracy customized machined parts that involves very minute details as well as do service that work with high precision.

CNC Milling describes a machine tool that generally makes use of a milling cutter to procedure various surface areas on the workpiece. Typically the rotating activity of the milling cutter is the main activity, and the airplane activity of the milling as well as the workpiece cutter is the feed motion.

While CNC Turning refers to a machine device that makes use of a turning tool to transform a rotating work surface. Usually, the turning tool is taken care of at a specific position on the maker device. The work surface rotates along the axis under the securing of the component as well as is reduced when it is close to the cutting edge, so it is primarily appropriate for refining shafts, disks, sleeves and also various other work surfaces with turning surface areas.

2. Which Parts Needs High Precision Turning?

The High accuracy CNC turning parts or customized parts have high need in mostly all sectors including automotive sector, biomedical market, aeronautics, instrumentation, robotics as well as several various other sectors.

3. How CNC Turning Works?

Like CNC milling, a CNC turning maker holds a block of material as well as the mechanism turns while material is eliminated to create the form. CNC turning is normally made use of to produce cylindrical-type forms as well as is a simple procedure:

4. Why Choose CNC Turning?

CNC turning is the fastest way to get rid of huge quantities of material on spherical stock. It's additionally ideal for bigger production runs when paired with an automated bar feeder that supplies a continuous supply of raw material into the machine.CNC turning is the only commercial procedure to choose when making manufacturing volumes of threaded features or concentric forms. And, because of the stiff building and construction of these equipments there is little resonance, which suggests CNC turning can supply high degrees of dimensional precision with excellent surface coatings.

Get Your CNC Turning Project Started Today

When you send us your 3D CAD file, JY Machinery will offer you instant pricing, on-demand preparation, and design-for-manufacturability responses on materials as well as making processes for your customized CNC turned components to guarantee that the component can be made to your expectations and budget needs. Call us today for a totally free quote!

Products Show:

X

X