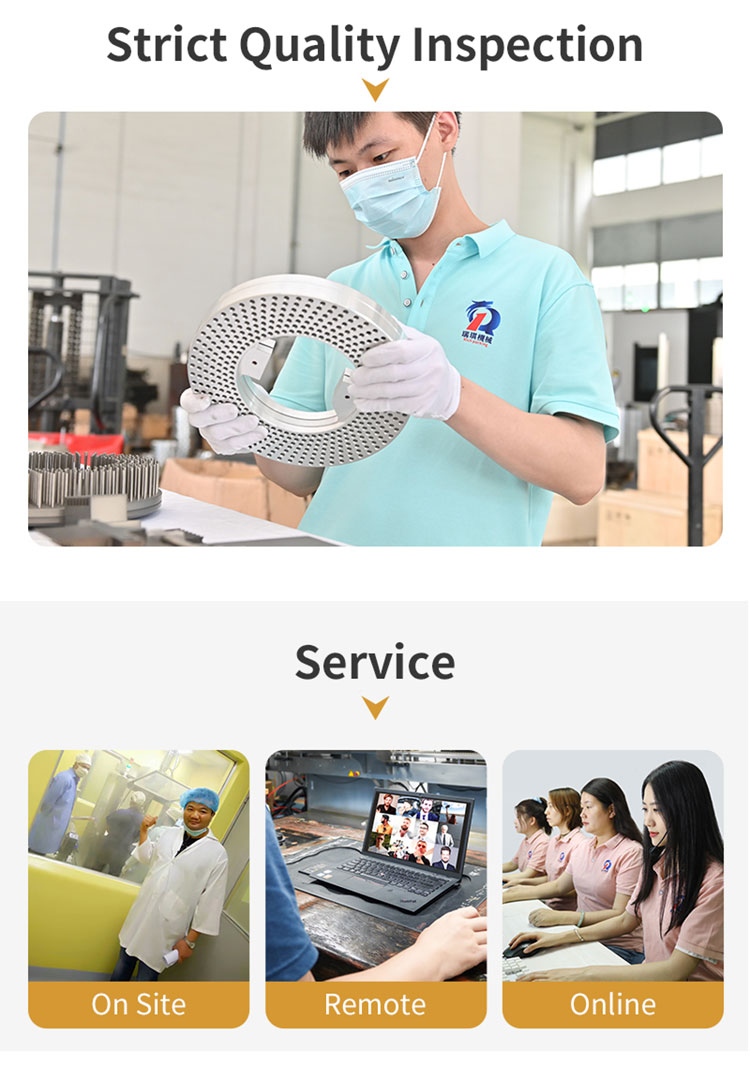

Factory Price and In Stock and two Week lead time, Producing Cgmp Semi semi automatic capsule filler machine Since 1993. Semi Automatic and Automatic meet your needs, Guaranteed For two Years. Semi Capsule Filling precision for size #000 to #5. CGN-208D machines have Passed SGS, CE, ISO, cGMP standard. Provide Door-To-Door field Oversea On-Site Service, On Site installation On Site Training and On Site Commissioning.

CGN-208D Hard Gelatin Semi Automatic Capsule Filling Machine

Our RICH PACKING company's Filling Capsule Filler Machine Semi Automatic realize fully automatic filled, place the capsuling tray manually, and then start to fill the capsule shell with medicine powder pellets and other materials is semi-automatic and can be delivered in 14 days after your pay, and provides a whole 3-year free warranty period. In order to facilitate the smooth working production of users after receiving the goods, we are briefly introduce the CGN 208D operating process of this.

1. After checked that the parts are intact, press the green button in the "Power Switch".

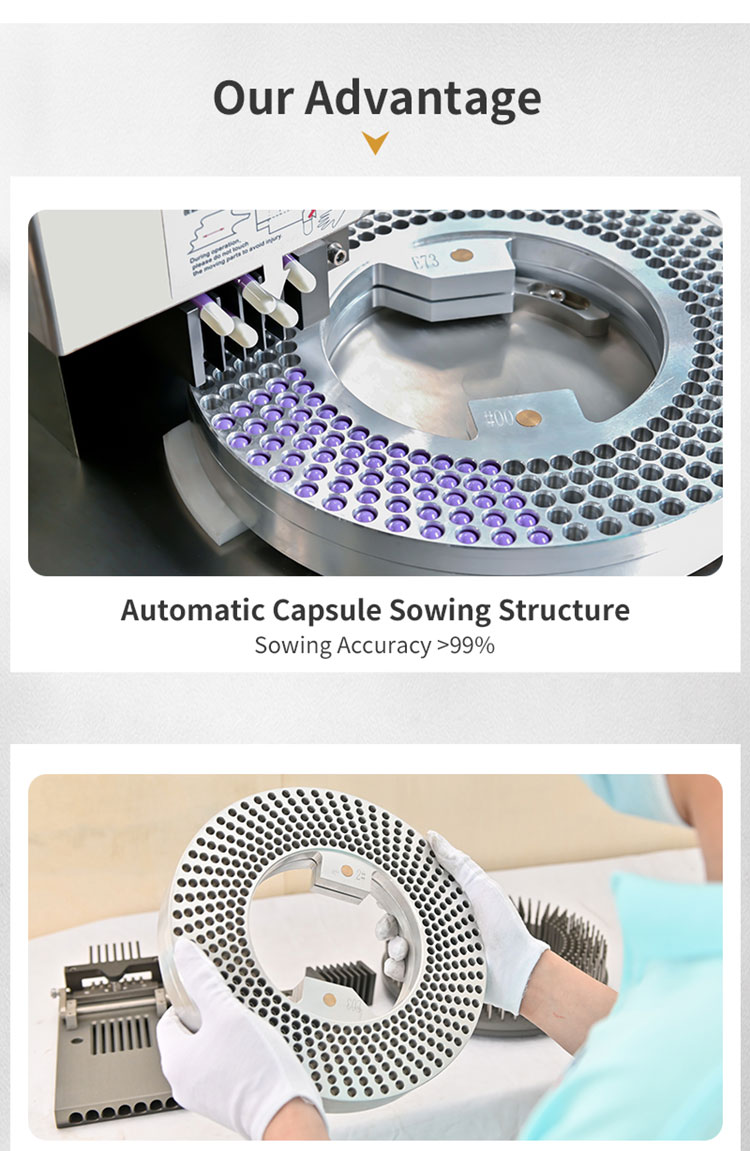

2. Slowly adjust the "vibration intensity adjustment knob" in the clockwise direction, touch the sorting plate with two hand, and adjust to a certain vibration intensity by the feeling.

3. Put the hollow capsules into the hopper, and control the quantity to be three-fifth of the hopper. Adjust the height of the outlet of the hopper to control the material discharge speed.

4. The hollow capsule and cap will be sucked into the disc by negative pressure air after the sanctification starts.

5. After sowing the capsules, rotate the capsule plate to the designated, then take out and place it in the filling position.

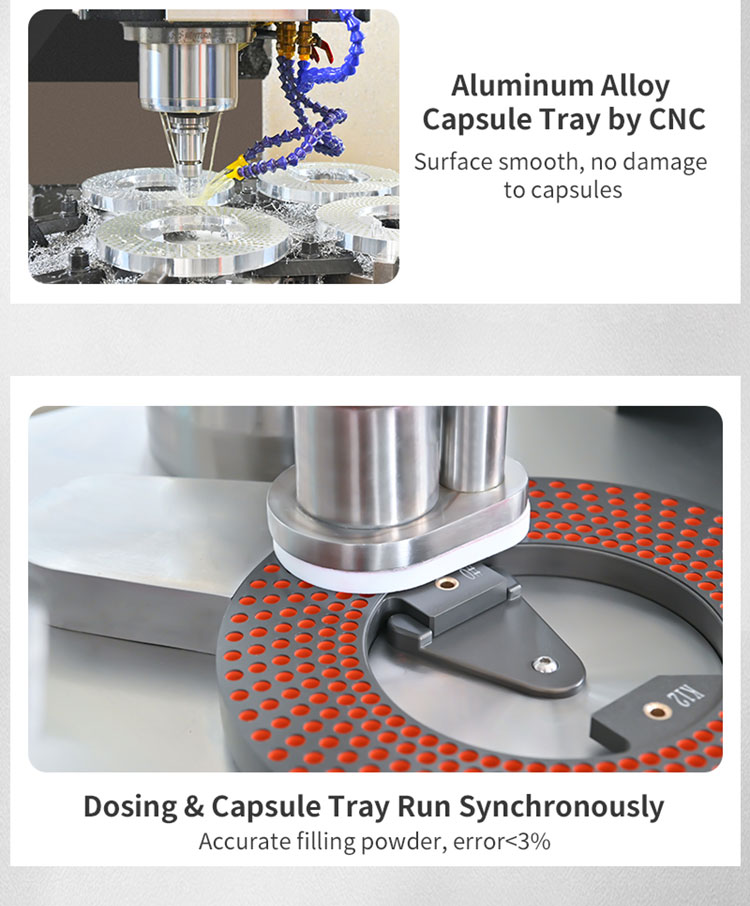

6. Press the green button of the capsule filling machinery, the material filling head will move to the position, and then the plates will rotate clockwise to proceed with the process.

7. Take out the filled capsule filling machine’s tray to the horizontal lock position, and then press the lock button at the same time.

*** Technical parameter

|

Model |

CGN-208D |

|

Max.Capacity |

30,000pcs/h |

|

Applicable capsule |

000#, 00#、0#、1#、2#、3#、4#、5# |

|

Power supply |

2.12kw |

|

Outline dim. |

1300*800*1750mm |

|

Net weight of machine |

400kg |

|

Gross weight of machine |

500 kg |

|

Packing size |

1640*720*1700mm |

X

X