Water Electrolysis Hydrogen Production

|

P/N |

ZXD-100 |

ZXD-120 |

ZXD-125 |

ZXD-150 |

ZXD-175 |

ZXD-180 |

ZXD-200 |

|

Hydrogen Production(m3/h) |

120 |

120 |

125 |

150 |

175 |

180 |

200 |

|

Oxygen Production(m3/h) |

50 |

60 |

62.5 |

75 |

87.5 |

90 |

100 |

|

Hydrogen Purity(V/V) |

≥99.99% |

≥99.99% |

≥99.99% |

≥99.99% |

≥99.99% |

≥99.99% |

≥99.99% |

|

Oxygen Purity(V/V) |

≥92.5% |

≥92.5% |

≥92.5% |

≥92.5% |

≥92.5% |

≥92.5% |

≥92.5% |

|

Operating load |

50%-100% |

50%-100% |

50%-100% |

50%-100% |

50%-100% |

50%-100% |

50%-100% |

|

Working Pressure(MPa) |

1.5~2.0 |

1.5~2.0 |

1.5~2.0 |

1.5~2.0 |

1.5~2.0 |

1.5~2.0 |

1.5~2.0 |

|

Hydrogen Moisture Content(g/m3) |

≤4 |

≤4 |

≤4 |

≤4 |

≤4 |

≤4 |

≤4 |

|

Hydrogen Alkalinity(mg/m3) |

≤1 |

≤1 |

≤1 |

≤1 |

≤1 |

≤1 |

≤1 |

|

Working Temperature(℃) |

85±5 |

85±5 |

85±5 |

85±5 |

85±5 |

85±5 |

85±5 |

|

Cooling water flow(m3/h) |

15 |

20 |

21 |

25 |

26 |

27 |

28 |

|

DC power consumption(kW·h/m3H2) |

≤4.3 |

≤4.3 |

≤4.3 |

≤4.3 |

≤4.3 |

≤4.3 |

≤4.3 |

|

External dimension of electrolyzer L×W×H (mm) |

2500x1650x1860 |

2850x1650x1860 |

2910x1650x1860 |

3350x1650x1860 |

3045x1885x2200 |

3100x1885x2200 |

3340x1885x2200 |

|

Electrolyzer Weight(kg) |

14100 |

15700 |

15900 |

17800 |

20700 |

21000 |

22100 |

|

Alkali concentration |

30% KOH |

30% KOH |

30% KOH |

30% KOH |

30% KOH |

30% KOH |

30% KOH |

|

Circulation quantity of alkali liquor(m3/h) |

6.5~8.0 |

7.5~10 |

7.5~10 |

8.5~12 |

12~14 |

12~14 |

13~15 |

Main Features

|

Closed Circulating Water System |

|

|

Cooling water circulation system is composed of cooling water tank, cooling water pump plate heat exchanger, butterfly valve, pipe and other heat exchange devices. |

|

|

Hydrogen Bus Bar |

|

|

Hydrogen bus bar is a hydrogen distribution system independently developed by Xiamen Zhongxinda Hydrogen Energy Technology Co., Ltd. |

Onsite hydrogen production

Electrolysers

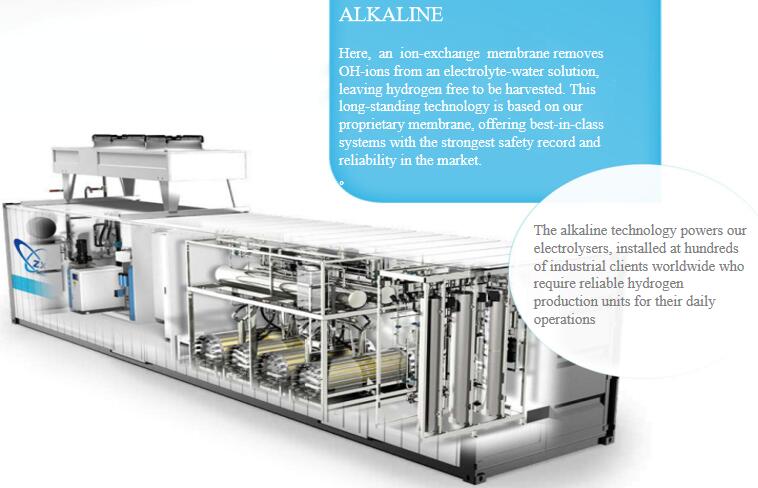

zxdh2 is a professional manufacturer of electrolysers, delivering onsite hydrogen production solutions. zxdh2’ electrolysers are ‘plug and play’ units, safely and reliably producing very pure hydrogen in continuous or dynamic operation modes.

All systems can be connected to standard power and water connections and are equipped with standard water purification, power conditioning, hydrogen purification and remote servicing. zxdh2 offers two types of technologies for the cell stack: pressurized alkaline and PEM (proton exchange membrane)

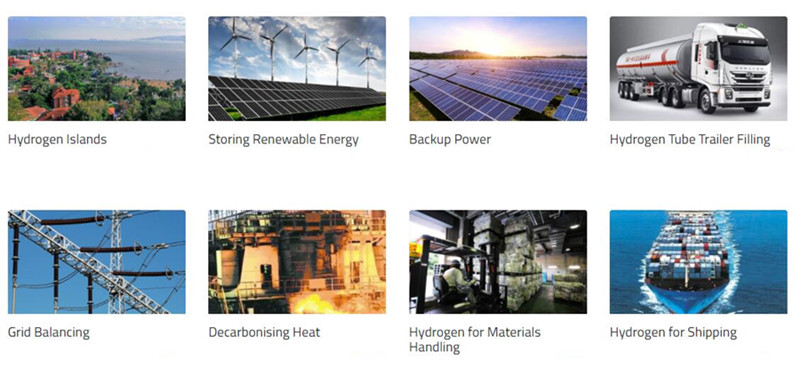

Application:

• Redundant renewable energy transformation and storage

• Lab experiment and teaching

• Laboratory analytic instrument

• Hydrogen healthy care industrial

• Hydrogen beauty industrial

• Fuel for special field

• Hydrogen supply for fuel cell

• Other pure H2 application field

Certification

X

X