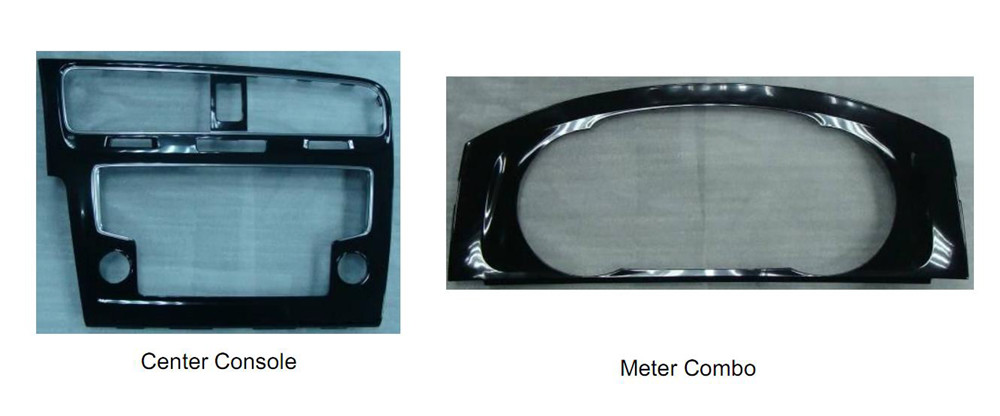

Automotive IMD ,2K ,3K series injection plastic mould

China specializes in plastic molds, car console injection mold manufacturers

JHS Mould has a strong design team to accept: provide samples, or, 3D drawings, 2D drawings, can quote for mold opening, you are welcome to consult and quote!

A variety of mold materials for your choice!

Injection molding is one of the most commonly used production processes for plastics. This is rightly so as it offers a viable solution for the mass production of high-quality injection automotive parts from a broad range of polymers. In the automotive industry, where consistency, safety, and quality are of utmost importance, automotive plastic injection molding is an important manufacturing process.

In the automotive industry, repeatability—or the ability to consistently produce identical parts—is crucial. Because automotive plastic injection molding typically relies on robust metal molds, the final molded automotive parts produced using the mold are practically identical. Some factors come into play with injection molding, but injection molding is a highly repeatable process if the mold has a good design and finishing.

| Name | Automotive IMD ,2K ,3K series injection plastic mould |

| Mold size | Custom Size |

| Mould material | 45#,50#,1.2312 ,1.2343 ESR,1.2738 HH , S136 ,NAK80 , SKD61 etc. |

| Mould base | LKM, HASCO ect. |

| Cavity | Single/multi |

| Runner | Hot/cold |

| Design software | UG, PROE, CAD, CAXA ect. |

| Mould life | 300,000-3,000,000 shots |

| Delivery time | 15-60days |

| Specification | Depends on customer's requirments |

| Shaping Mode | Plastic Injection Mould |

| Molding life | 500,000-5,000,000shots |

| Delivery time | Short mold development cycle |

| Packing | Standard exporting wooden case |

1) Receive customer's inquiry

2) We will quote guests within 24 hours

3) Confirm the order (price, payment terms, delivery date)

4) Product analysis (DFM)

5) After DFM confirmation by customer

6) Confirmation of mold design

7) Purchase steels and start machining processing

8) Inspection process

9) Mold core inspection is OK, start assembly

10) Tool tryout and deliver the samples to customer

11) Get feedback of samples from customer.

12) If there is a problem with the sample, repair the mold

13) After repaired , tryout and deliver samples to customer for confirmation again

14) After the sample is confirmed that there is no problem, the mold is arranged to be shipped

Please send 3D/2D drawing or samples to us if you have any needs, we will quote for free with a sound price.

|

|

1.Strong Capability:Our experienced prototype injection molding services provide full list of injection molding processes, along with 100+ materials and surface finishes to suit your custom injection molding needs.

2.High efficiency:As an injection molding manufacturer in China, we provide affordable injection molding quotes within 1 business day. In addition, no MOQ rapid injection molding makes it feasible for initial development.

3.Reliable quality:Quick turn Injection molding with RapidDirect is at ease. We provide free DFM feedback, certifications and production update through the process. You always get high quality custom molded plastic parts.

4.Rapid tooling:Fast and cost-effective process to create aluminum or steel injection molds for quick turn injection molding. Ideal for rapid prototyping needs or validating product concept for production.

JHS is committed to the research and development, design and manufacture of various injection molds, and injection production, involving industries and fields such as electronics, automobiles, communications and household appliances.

The distinction between IMD, IML, IMR, and IMF

IMD: In-Mole Decoratiom, IMD is the current international popular surface decoration technology, mainly used in the surface decoration and functional panels of home appliances, commonly used in mobile phone window lenses and shells, washing machine control panels, refrigerator control panels, air conditioner control panels, Appearance parts such as panels and signs in various fields of automobile dashboards and rice cooker control panels.

IMD is divided into IML and IMR. The biggest difference between these two processes is whether there is a transparent protective film on the surface of the product.

IML: In-mold insert injection molding. Its very distinctive features are: the surface is a hardened transparent film, the middle is a printed pattern layer, and the back is a plastic layer. Because the ink is sandwiched in the middle, the product can prevent the surface from being scratched and scratched. Wear-resistant, and can keep the color bright and not easy to fade for a long time.

IMR: In-mold transfer

In this process, the pattern is printed on the film, and the film is attached to the mold cavity by a film feeder for injection molding. After injection molding, the patterned ink layer is separated from the film, and the ink layer is left on the plastic part to obtain a decorative pattern on the surface. There is no transparent protective film on the surface of the final product, and the film is only a carrier in the production process. But the advantage of IMR is the high degree of automation in production and the low cost of mass production. Disadvantages of IMR: The printed pattern layer is on the surface of the product with a thickness of only a few microns. After the product is used for a period of time, the printed pattern layer is easily worn off, and it is also easy to fade, resulting in an unsightly surface. In addition, the new product development cycle is long, the development cost is high, and the pattern color cannot be flexibly changed in small batches, which are also weaknesses that the IMR process cannot overcome.

First of all, it is necessary to explain the concept:

IMD includes IML, IMF, IMR

IML: IN MOLDING LABEL ﹝ Printing rubber and plastic combination ﹞

IMF: IN MOLDING FILM (same as IML)

IMR: IN MOLDING ROLLER﹝The focus is on the release layer on the rubber compound. PET FILM → printing release agent → printing ink → printing adhesive → inner plastic injection → ink and plastic bonding → the rubber material will automatically release from the ink after the mold is opened. In Japan, it is called thermal transcription. This machine uses the ROLL TO ROLL method, and the alignment is operated by a CCD computer. ﹞

At present, some people in China call IMR IMD, and IML is independent of IMD. The most fundamental difference is the difference between IML and IMR on the lens surface, IML has PET or PC sheet on the surface, while IMR has only ink on the surface. IMD is a relatively complicated process, and there are only a handful of domestic manufacturers with relatively mature technology, so I can only introduce a little bit of fur, please bear with me.

IML's sheets are made of PET or PC. This may be different from the last post. It may be that the technical level of each company is different. I don't think I need to explain more about the material of PET and PC. Plastic particles generally use PMMA and ABS. IML and IMR have their own advantages. IMR is not very wear-resistant. Some of Nokia and Moto’s mobile phones use IMR technology, which will cause scratches if it takes a little longer. a certain area.

Traditional decorative injection moulding processes produce a wide variety of plastics such as: pressure-sensitive adhesive labels, shrink oversleeve labels; primer and offset prints; thermal transfer foils; decals And so on, all fall into this category. All of these products require secondary processing to be made, and their production process has recently faced challenges from a one-step production process, which is "In-Mold Labeling" (In-Mold Labeling). The so-called in-mold labeling technology (IML) can make various parts processed by plastic product manufacturers look like "without labels", and the quality of the printed label patterns cannot be achieved by some post-color decoration methods. of. For example, image photos, undulating patterns, and even three-dimensional holographic patterns can be used as an integral part of the product, and the quality effect is better than those of products with labels on the outer surface. The plastic products processed and produced by the in-mold labeling process are more decorative in structure, and the quality of the packaging products can be reduced by 10% to 15%, while the strength of the side walls of the products is increased at the same time.

In-mold labeling process products are designed in a variety of styles, from flat lids of various shapes to 360° wrap-around labels, and products with 3, 4, 5, and even 8 sides can be designed. Rectangular, circular, square products with rounded corners, or products with corrugated side patterns. This is a unique technology where the "label" is made by simply wrapping a piece of moulded plastic liner around a piece of printed cardboard to create a complete flange.

CNC Machining Workshop

EDM Workshop

Quality Inspection Department

Wire Cutting Workshop

Injection Workshop

Assembly Workshop

Q: Do you make molds for many auto parts?

A: Yes, we make molds for many auto parts, such as bumpers, reversing radar parts, car control panels, rearview mirror brackets, etc.

Q: Do you have injection molding machines to produce parts?

A: Yes, we have our own injection workshop, so we can produce and assemble according to customer requirements.

Question: What kind of mold do you make?

A: We mainly manufacture injection molds, but we can also manufacture compression molds (for UF or SMC materials) and die casting molds.

Q: How long does it take to make a mold?

A: Depending on the product size and the complexity of the parts, it is slightly different. Generally speaking, a medium-sized mold can complete T1 within 25-30 days.

Q: Can we know the mold schedule without visiting your factory?

A: According to the contract, we will send you the mold production plan. During the production process, we will update you with weekly reports and related pictures. Therefore, you can clearly understand the mold schedule.

Q: How do you guarantee the quality?

A: We will appoint a project manager to track your molds, and he will be responsible for each process. In addition, we have QC for each process, and we will also have a CMM and online inspection system to ensure that all components are within tolerance.

Q: Do you support OEM?

A: Yes, we can produce through technical drawings or samples.

X

X