3/4 Way ball valve has T type,L type and X type. T type can make three orthogonal pipes connect with each other and cut off the third channel, and play the role of shunt and confluence. L type way ball valve type can only connect two pipes with each other orthogonal, can not keep the third pipe interconnected at the same time, only play the role of distribution.

3 way ball valve flange end direct mounting pad

Ball valve characteristics:

1. pneumatic 3/4 way ball valve, three way ball valve in the structure of the integrated structure, four-sided seat sealing type, less flange connection, high reliability, designed to achieve lightweight

2. 3/4 way ball valve long service life, large circulation capacity, small resistance

3. 3/4 way ball valve is divided into two types according to action type and double action type. The characteristic of single action type is that once the power source fails, the ball valve will be in the state required by the control system

Ball valves and gate valves are valves of the same type, except that the closing part is a ball, and the ball rotates around the center line of the valve body to achieve opening and closing. Ball valve in the pipeline is mainly used to cut, distribute and change the flow direction of the medium. Ball valve is a new type of valve widely used.

3 way ball valve Advantages:

1. the fluid resistance is small, its resistance coefficient is equal to the pipe section of the same length.

2. structure is simple, small size and light weight.

3.Close and reliable good sealing, in the vacuum system has been widely used.

4. operation is convenient, open and close quickly, from full open to full close as long as rotating 90°, easy to remote control.

5. maintenance is convenient, ball valve structure is simple, sealing ring is generally active, disassembly and replacement are more convenient.

6. when fully open or closed, the sealing surface of the ball and seat is isolated from the medium, and when the medium passes, it will not cause erosion of the valve sealing surface.

7. wide range of application, diameter from small to a few millimetres, large to a few meters, from high vacuum to high pressure can be applied.

High platform ball valve can be divided into straight-through type, three-way type and right-angle type according to its channel position. The latter two ball valves are used to distribute the medium and change the flow direction of the medium.

Working methods:

L type of three-way 4-sided valve seat valve with 2-sided valve seat. mainly used for commutation of flow paths.

T type of three-way four-sided valve seat ball valve, using four-sided valve seat, force balance, to ensure reliable sealing on the closed channel. Mainly used for diversion, mixing, reversing and the complete opening of the three channels.

3 way ball valve features:

1. Reduced port T port/ L port/ X port, 1/2"~6" (DN15~DN150)

2. W.P.: CLASS 150/300 PN16/40 10K

3. W.T.: -20℃~180℃ ANSI CLASS 150

4. Investment casting Design: ASME B16.34,API608,API6D

5. Blow-out proof stem Flange dimension: ASME B16.5

6. Live-loading design Inspection & testing:API 598

7. Anti-static device (option) DIN PN16

8. There are four seats Design: EN 1983,EN 12516-1

9. 360° Rotary handle Flange dimension: EN1092-1,PN16/40

10.Locking device handle Inspection & testing: EN12266-1

11.ISO 5211 Direct mounting pad JIS 10K

12.Automation accessories (option) Design: JIS B2071

Flange dimension: JIS B2071

Inspection & testing: JIS B2003

Material List

|

||||

|

No. |

PARTS |

MATERIAL |

||

|

1 |

BONNET |

WCB |

CF8 |

CF8M |

|

2 |

GASKET |

PTFE |

||

| 3 | SEAT |

PTFE |

||

|

4 |

BALL | CF8 | CF8 | CF8M |

| 5 | BODY | WCB | CF8 | CF8M |

| 6 | BOLT |

304 |

||

|

7 |

STEM | 304 | 304 | 316 |

| 8 | STEM WASHER | PTFE+25% GF | ||

|

9 |

O-RING |

FPM |

||

| 10 | PACKING |

PTFE |

||

| 11 | WEAR WASHER | PTFE+25% GF | ||

| 12 | GLAND | 304 | ||

|

13 |

DISC SPRING | 304 | ||

|

14 |

HEX SOCKET BOLT | 304 | ||

|

15 |

NUT | 304 | ||

|

16 |

HANDLE | WCB/CF8 | ||

| 17 | STOPPER | 304 | ||

| 18 | GLAND FLANGE | CF8 | ||

| 19 | BOLT | 304 | ||

| 20 | NUT | 304 | ||

| 21 | TEE | WCB/CF8 | ||

| 22 | HEX SOCKET SET SCREW | 304 | ||

| 23 | HANDLE | Q235A | ||

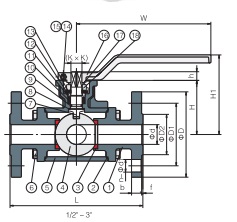

Unit:mm

Dimensions

|

||||||||||||||||||

|

Nominal Diameter |

L |

d |

D2 |

D1 |

D |

b |

f |

n-φd1 |

H |

h |

H1 |

W |

Ra |

Rb |

A |

B |

KxK |

|

|

15 |

1/2" |

150 | 15 | 35 | 60.3 | 90 | 10 | 2 | 4-16 | 50 | 9 | 82 | 140 | 3.0 | 3.5 | 36 | 50 | 9X9 |

|

20 |

3/4" | 165 | 20 | 43 | 70 | 100 | 10.5 | 2 | 4-16 | 60 | 9 | 92 | 140 | 3.0 | 3.5 | 36 | 50 | 9X9 |

|

25 |

1" | 181 | 25 | 51 | 79.4 | 110 | 10.5 | 2 | 4-16 | 65 | 11 | 100 | 170 | 3.0 | 3.5 | 42 | 50 | 11X11 |

|

32 |

1-1/4" | 190 | 32 | 63.5 | 88.9 | 115 | 11.2 | 2 | 4-16 | 80 | 11 | 115 | 170 | 3.0 | 3.5 | 42 | 50 | 11X11 |

|

40 |

1-1/2" | 212 | 40 | 73 | 98.4 | 125 | 12.7 | 2 | 4-16 | 90 | 14 | 128 | 200 | 3.5 | 4.5 | 50 | 70 | 14X14 |

|

50 |

2" | 229 | 50 | 92 | 120.7 | 150 | 14.3 | 2 | 4-19 | 106 | 14 | 144 | 200 | 3.5 | 4.5 | 50 | 70 | 14X14 |

| 65 | 2-1/2" | 290 | 65 | 105 | 139.7 | 180 | 15.9 | 2 | 4-19 | 118 | 17 | 162 | 300 | 4.5 | 5.5 | 70 | 102 | 17X17 |

|

80 |

3" | 310 | 80 | 127 | 152.4 | 190 | 17.5 | 2 | 4-19 | 128 | 17 | 172 | 300 | 4.5 | 5.5 | 70 | 102 | 17X17 |

|

100 |

4" | 368 | 100 | 157 | 190.5 | 230 | 22.3 | 2 | 8-19 | 165 | 25 | 250 | 650 | 5.5 | 6.5 | 102 | 125 | 22X22 |

| 125 | 5" | 420 | 125 | 185 | 216 | 255 | 22.3 | 2 | 8-22 | 212 | 30 | 297 | 800 | 5.5 | 6.5 | 102 | 125 | 27X27 |

| 150 | 6" | 480 | 150 | 216 | 241.3 | 280 | 22.3 | 2 | 8-22 | 243 | 30 | 328 | 800 | 5.5 | 6.5 | 102 | 125 | 27X27 |

Packing & Delivery :

Packing Details: all 3 way ball valve by seaworthy plywood case and packed strongly by packing belt as below

Delivery Details: Generally it is 5-10 days if the goods are in stock. or 15-30 days if the goods are OEM or not enough subject to the order quantity. But anyway, normally, we are able to make sure the delivery will not exceed 45 days.

X

X