Our company and Chinese academy of sciences jointly developed a new intelligent die casting machine. Features: high energy saving, simple operation, fast injection speed, high yield.

200T cold chamber die casting machine spare parts

Parameters of cold chamber die casting machine(200T)

|

Items |

Unit |

Specification |

|

Hydraulic Working Pressure |

MPa |

14 |

|

Clamping Force |

KN |

2000 |

|

Space Between Tie Bars |

mm |

480*480 |

|

Tie Bar Diameter |

mm |

¢85 |

|

Die Opening Stroke |

mm |

380 |

|

Injecction Force(intensify) |

KN |

270 |

|

Plunger launch distance |

mm |

135 |

|

Injection position |

mm |

0 -- 140 |

|

Plunger Diameter |

mm |

¢50----¢70 |

|

Injection Stroke |

mm |

350 |

|

Casting pressure (intensify) |

MPa |

112/78/57 |

|

Casting Fiange Protrusion |

mm |

10 |

|

Casting Fiange Diameter |

mm |

110 |

|

(40Mpa) Max Casting Area Under 40Mpa |

CM2 |

450 |

|

lnjection Weight(Al) |

Kg |

2.4 |

|

Die Height(Min--Max) |

mm |

200~550 |

|

Ejector Force |

KN |

110 |

|

Ejector Steoke |

mm |

80 |

|

Motor Capacity |

Kw |

15 |

|

Machine Dimensions (L*W*H) |

m |

5.32*1.5*2.35 |

|

Referential Machine Weight For Uplifting |

T |

7 |

|

Oil Tank Capacity |

L |

600 |

WE reserve the right to make any technical improvement without further notice

1.Adopts high and low pressure-- twin pump with high performance and low noise, saves energy consumption and improves production efficiency .

2.Adopts automatic concentrated lubrication system ,directly sets lubrication for times of machine operation and improves service life of the machine and decrease repair

3.There are two intensification activation way:pressure and position that satisfy all kinds of processing requirements.

4.NFP:Injection system with the simple structure,high reliability and durability,accurate control and non-interference with injection system.

1. Double proportional control (electric regulation of pressure and flow, with a multi-level pressure and Speed control as well as low pressure die close protection functions).

2. Dual circuit design (air injection and pressure building are separately designed without mutual interference and fault occurrence).

Packaging and delivery of die casting machines:

We have our own factory, containers can be directly from the factory to extract die-casting machine and related machine parts. Our packing is standard packing. The wooden cases we use are for export use only.

Die casting machine products:

Engine cylinder block, cylinder head, crankcase, hinged door covers, oil pan, gearbox housing, gearbox end cap, dashboard, etc.

Electric escalator handrail/steps,industrial/road/railway/air/agricultural machinery, spotlight shells, building material parts, furniture, aluminum arts, copper arts, magnesium alloy products, non-ferrous metal processed products and other die casting products.

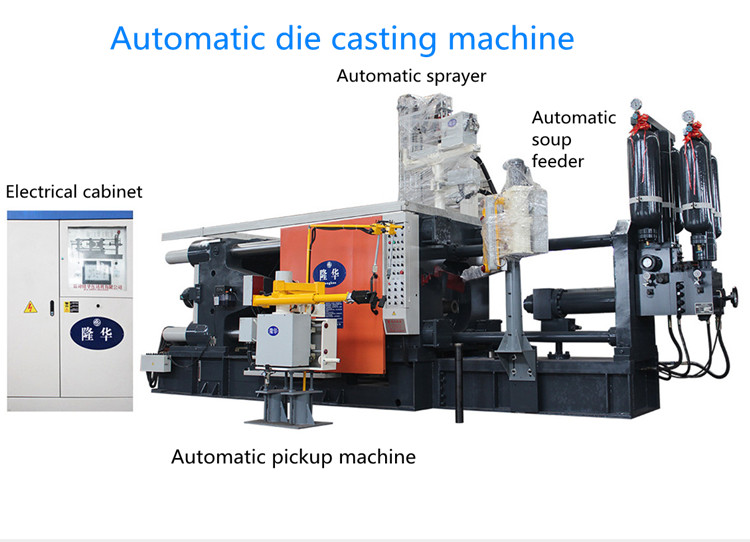

Auto die casting machine composition

X

X